Aluminum straight ladders have evolved significantly over the years, becoming a staple in various industries and households due to their lightweight yet durable construction. Originally introduced as an alternative to traditional wooden ladders, aluminum ladders quickly gained popularity for their corrosion resistance, strength-to-weight ratio, and ease of maintenance.

Modern aluminum straight ladders are manufactured using advanced techniques that ensure precision and reliability. The production process begins with high-quality aluminum alloys, carefully selected for their strength and durability. These alloys undergo extrusion or rolling processes to form the ladder's structural components, such as the side rails and rungs.

One of the key advantages of aluminum ladders is their lightweight nature, which makes them easy to transport and maneuver. This characteristic is particularly beneficial in industries such as construction and maintenance, where workers frequently need to move ladders between different locations. Despite their light weight, aluminum ladders are robust and capable of supporting significant loads, providing a safe working platform for various tasks.

Aluminum ladders are also favored for their resistance to rust and corrosion, unlike their steel counterparts. This makes them suitable for outdoor use and environments where exposure to moisture is common. Additionally, aluminum does not require painting or sealing to maintain its durability, reducing maintenance efforts and costs over time.

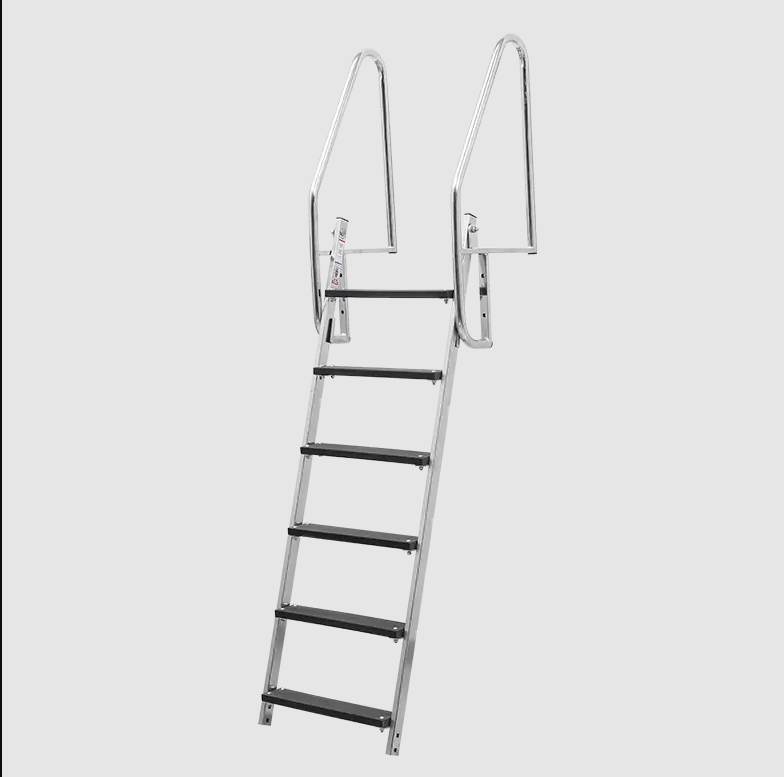

In terms of design, aluminum straight ladders come in various configurations to meet specific user needs. Single-section ladders are straightforward and ideal for tasks that require constant elevation, such as painting or ceiling repairs. Extension ladders offer adjustable heights for accessing different levels, while platform ladders provide a stable working platform with a wider base.

Overall, aluminum straight ladders continue to be a preferred choice for professionals and homeowners alike due to their strength, durability, and versatility. As manufacturing techniques and material advancements progress, these ladders are expected to further evolve to meet the demands of modern work environments and safety standards.