In the intricate world of manufacturing, the Plastic Crate Mould Factory stands as a testament to precision, innovation, and efficiency. The process of creating molds for plastic crates is a complex one, involving a series of meticulous steps that ensure the end product is both functional and durable. This article aims to shed light on the production process within a Plastic Crate Mould Factory, exploring the various stages that contribute to the creation of these essential industrial components.

The journey begins with the design phase, where engineers and designers collaborate to create a blueprint for the plastic crate mold. This stage is critical, as it sets the foundation for the entire production process. Designers must consider factors such as the crate's intended use, the materials to be used, and the necessary strength and durability requirements. Once the design is finalized, it is translated into a digital format that can be used to guide the manufacturing process.

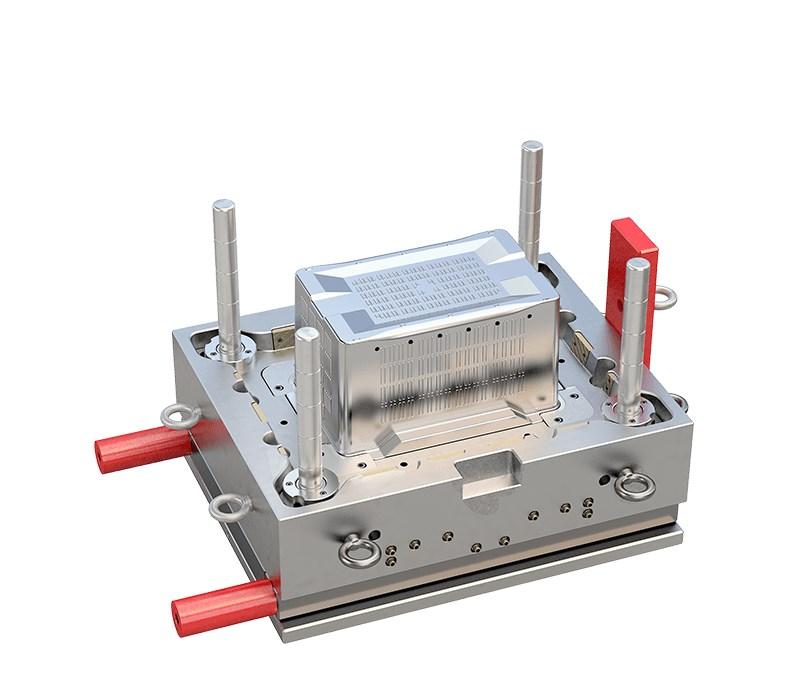

The next step in the Plastic Crate Mould Factory's production process is the creation of the mold itself. This involves the use of state-of-the-art CNC (Computer Numerical Control) machines that carve the mold from a solid block of steel or aluminum. The precision of these machines is paramount, as even the slightest deviation can result in a mold that does not meet the required specifications. The CNC process is followed by a series of finishing touches, including polishing and the application of a protective coating to ensure the longevity of the mold.

Once the mold is ready, it is transported to the injection molding department within the Plastic Crate Mould Factory. Here, the mold is loaded into an injection molding machine, which heats and melts the plastic material before injecting it into the mold under high pressure. The mold is then cooled, allowing the plastic to solidify and take the shape of the crate. The mold is opened, and the newly formed plastic crate is removed, ready for further processing.

The post-molding process is an essential part of the Plastic Crate Mould Factory's production line. It involves trimming any excess plastic, smoothing rough edges, and ensuring that the crate meets all quality control standards. This stage also includes the application of any necessary reinforcements or additional features, such as handles or lids.

Quality control is a continuous and integral part of the Plastic Crate Mould Factory's operations. Each crate is inspected for defects, and the molds are regularly checked for wear and tear to ensure that they continue to produce crates of the highest quality. The use of advanced inspection equipment and rigorous testing protocols ensures that only the best products leave the factory.

Finally, the completed plastic crates are packaged and prepared for shipment. The Plastic Crate Mould Factory must also consider the logistics of distribution, ensuring that the crates reach their destination in perfect condition. This involves careful packaging and the use of reliable transportation methods.

In conclusion, the production process within a Plastic Crate Mould Factory is a symphony of design, engineering, and manufacturing expertise. From the initial design phase to the final packaging and distribution, each step is carefully orchestrated to produce high-quality plastic crates that meet the needs of a wide range of industries. The attention to detail and commitment to quality that characterizes the Plastic Crate Mould Factory's operations is what sets it apart in the competitive world of manufacturing.