The production of a crystal glass pendant is a meticulous process that requires a keen eye for detail and a commitment to quality. These delicate and sparkling pieces of jewelry are not only admired for their beauty but also for the craftsmanship that goes into creating them. Ensuring the quality of crystal glass pendants involves a multi-faceted approach that begins with the selection of raw materials and extends through to the final inspection.

The journey of a crystal glass pendant starts with the selection of high-quality raw materials. The purity of the glass used is paramount, as it directly impacts the clarity and brilliance of the final product. Manufacturers must source their materials from reliable suppliers who can guarantee the consistency and purity of the glass.

Once the raw materials are secured, the process moves to the skilled artisans who shape and form the crystal glass into the desired pendant design. The craftsmanship involved in this stage is critical, as it requires a delicate touch and an eye for precision. Each pendant is carefully crafted to ensure that it meets the design specifications and maintains the structural integrity necessary for durability.

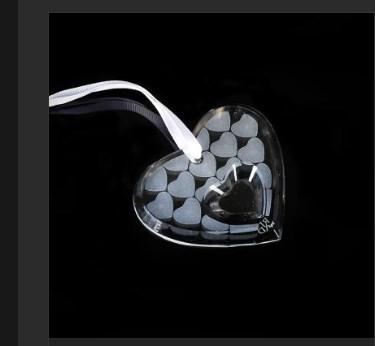

The cutting and polishing process is where the crystal glass pendant truly comes to life. Skilled craftsmen use precise tools to cut the glass into the desired shapes and facets, which are then polished to a high gloss. This stage is crucial for enhancing the aesthetic appeal of the pendant, as the cuts and polish determine the way light interacts with the glass, creating a dazzling effect.

Throughout the production process, quality control checks are conducted to ensure that each crystal glass pendant meets the highest standards. These checks include visual inspections for any imperfections, as well as mechanical tests to ensure the pendant's durability. Any piece that does not meet the stringent quality criteria is set aside for rework or discarded.

In addition to traditional craftsmanship, modern technology plays a significant role in the production of crystal glass pendants. Advanced machinery and computer-aided design (CAD) software are used to create intricate designs with a high degree of accuracy. This not only improves the efficiency of the production process but also ensures that each pendant is consistent in quality and design.

The production of crystal glass pendants also takes into account environmental sustainability. Manufacturers are increasingly adopting practices that minimize waste, reduce energy consumption, and use eco-friendly materials. This commitment to sustainability not only benefits the environment but also enhances the reputation of the brand and its products.

Finally, the feedback from customers is invaluable in the ongoing quest for quality. Manufacturers must be receptive to customer feedback and use it to make improvements in the design and production process. This continuous improvement loop ensures that the crystal glass pendants remain relevant and meet the evolving needs and preferences of consumers.

In conclusion, the production of a crystal glass pendant is a complex process that involves careful attention to detail at every stage. From the selection of raw materials to the final quality control checks, each step is crucial in ensuring that the pendants are of the highest quality. By combining traditional craftsmanship with modern technology and a commitment to sustainability, manufacturers can produce crystal glass pendants that are not only beautiful but also of exceptional quality.