With the continuous improvement of environmental protection awareness, more and more enterprises have begun to pay attention to energy conservation and environmental protection issues. In industrial production, the condenser is a very important piece of equipment, and its energy-saving and environmental protection features are crucial to the sustainable development of enterprises. As a new type of condenser, the air-cooled condenser has many advantages. Let's take a look at it in detail below.

Energy-saving features of air-cooled condensers

1. No need for water resources

Traditional water-cooled condensers require a large number of water resources for cooling, while air-cooled condensers do not require water resources and only need to use natural wind to dissipate heat. This not only saves water resources but also reduces water treatment and discharge costs.

2. Low operating cost

Air-cooled condensers also have lower operating costs than water-cooled condensers because they do not require additional water pumps and water treatment equipment, reducing energy consumption and maintenance costs.

3. Reduce energy consumption

The air-cooled condenser does not need electricity to drive the water pump, reducing electricity consumption and carbon dioxide emissions.

Environmental protection features of air-cooled condenser

1. Reduce the use of chemicals

Traditional water-cooled condensers require a lot of chemicals to prevent scale and corrosion, which will pollute the environment. The air-cooled condenser does not need to use these chemicals, which reduces the pollution to the environment.

2. Reduce greenhouse gas emissions

The air-cooled condenser does not need electricity to drive the water pump, reducing electricity consumption and carbon dioxide emissions.

3. Reduce water treatment and discharge costs

The air-cooled condenser does not need to use water resources, reducing the cost of water treatment and discharge.

Other Advantages of Air-Cooled Condensers

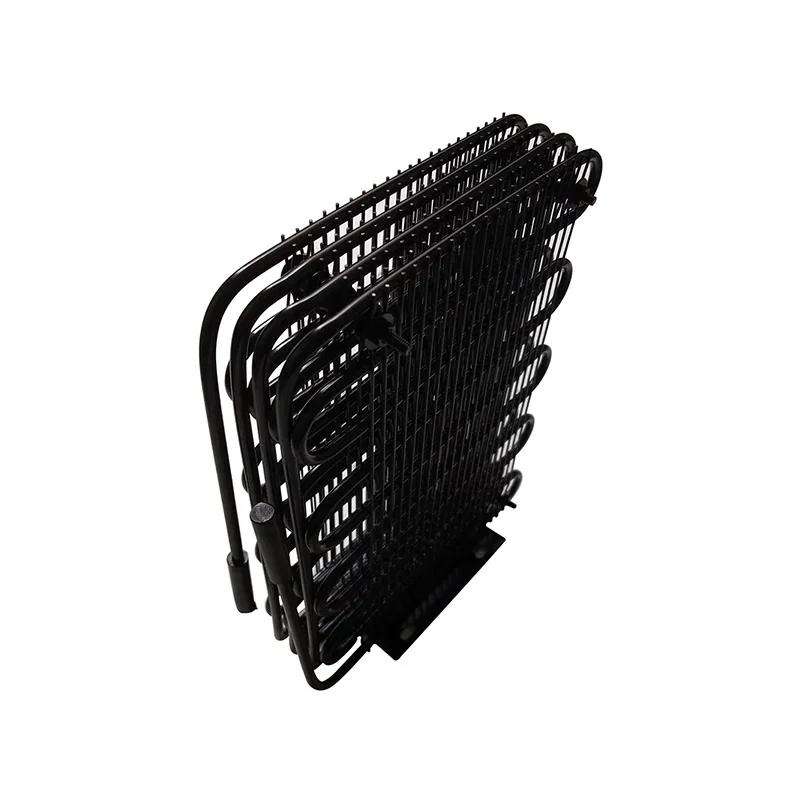

1. Simple structure

The structure of the air-cooled condenser is relatively simple, easy to maintain, and not prone to failure.

2. Good cooling effect

The heat dissipation effect of the air-cooled condenser is better than that of the water-cooled condenser, which can dissipate the heat in a short time and improve production efficiency.

3. Wide range of application

Air-cooled condensers are suitable for various industrial production fields, such as chemical, pharmaceutical, food, etc.

Application cases of air-cooled condensers

1. Chemical Industry

In the chemical industry, it can be used to cool various chemical substances, such as acids, alkalis, salts, etc. Due to the complex properties of chemical substances, traditional water-cooled condensers are difficult to meet the requirements, while air-cooled condensers can meet different cooling needs by adjusting the air volume and wind speed.

2. Pharmaceutical industry

In the pharmaceutical industry, it can be used to cool various medicines and intermediates. Due to the relatively high purity requirements of pharmaceuticals and intermediates, traditional water-cooled condensers are difficult to meet the requirements, while air-cooled condensers can meet different cooling needs by adjusting the air volume and air speed.

3. Food industry

In the food industry, it can be used to cool various foods and beverages. Due to the relatively high hygienic requirements of food and beverages, traditional water-cooled condensers are difficult to meet the requirements, while air-cooled condensers can meet different cooling needs by adjusting the air volume and wind speed.

With the continuous improvement of environmental protection awareness, the application range of air-cooled condensers will become more and more extensive. In the future, it will become one of the indispensable equipment in industrial production. At the same time, with the continuous advancement of technology, its performance will continue to improve, and its cost will continue to decrease, enabling more companies to achieve the goals of energy saving and environmental protection.