An injection machine manipulator is a robotic system designed to automate the handling of molded products in an injection molding process. These manipulators are particularly useful in industries where high volumes of parts need to be produced with precision and consistency. They help reduce cycle times, enhance safety, and improve overall production efficiency.

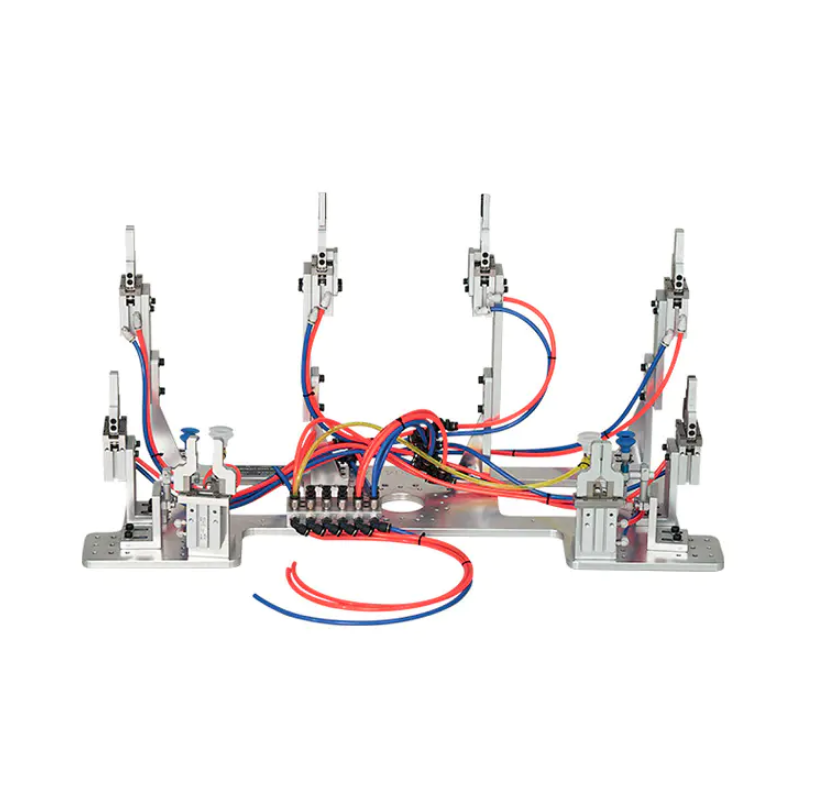

The core function of an injection machine manipulator is to remove molded parts from the injection mold and transport them to another location, such as a conveyor or collection tray. After the plastic is injected into the mold and allowed to cool, the manipulator’s arm extends into the mold to retrieve the part. The arm’s design typically includes an end-effector, such as a gripper or suction device, which ensures a secure hold on the part while preventing damage.

One of the primary advantages of an injection machine manipulator is its ability to operate with high speed and precision. The manipulator is programmed to perform tasks with exact timing, ensuring that parts are removed from the mold at the optimal moment. This helps avoid defects such as warping or incomplete molding. Additionally, manipulators help reduce the risk of injury to workers by removing them from the immediate vicinity of the injection machine, which can operate at high temperatures and pressures.

Injection machine manipulators are highly customizable, with options available for handling various part sizes and weights. Some systems are designed for simple part removal, while others can perform additional tasks, such as sorting, inspecting, or packaging parts. The integration of sensors and control systems allows the manipulator to adapt to changing conditions in the production environment, enhancing flexibility and reliability.

In conclusion, an injection machine manipulator plays a vital role in modern injection molding processes, improving efficiency, safety, and the overall quality of molded products. Its automation capabilities make it an invaluable tool in high-volume manufacturing environments.