Hydraulic Buffer Hinges, with their controlled closing action, play a significant role in enhancing the safety of various applications. From cabinetry in kitchens to doors in industrial settings, these hinges have become a preferred choice for their ability to prevent injuries and damage associated with sudden closures. The safety aspect of Hydraulic Buffer Hinges is multifaceted, involving both the protection of users and the preservation of the integrity of the items they are attached to.

In environments where doors and lids are frequently opened and closed, such as in commercial kitchens or workshops, the risk of accidents due to rapid closures is high. Hydraulic Buffer Hinges mitigate this risk by providing a slow and controlled closing mechanism. This feature not only prevents users from being injured by a sudden impact but also reduces noise pollution, which is beneficial for workplace health and safety.

The safety benefits of Hydraulic Buffer Hinges extend to the protection of the equipment and infrastructure they are used on. Sudden and forceful closures can lead to damage over time, especially in materials such as wood or glass. By slowing down the closing speed, Hydraulic Buffer Hinges help to extend the lifespan of these materials and reduce the need for frequent replacements, thereby saving costs associated with maintenance and repairs.

One of the key safety features of Hydraulic Buffer Hinges is their ability to prevent "finger pinching." Traditional hinges can cause severe injuries when a door or lid closes too quickly, trapping fingers in the process. Hydraulic Buffer Hinges, with their gradual closure, eliminate this risk, making them an ideal choice for environments where children or the elderly are present.

Another aspect of safety that Hydraulic Buffer Hinges contribute to is the prevention of damage to the contents within cabinets or enclosures. For example, in a kitchen, a sudden closure could cause dishes or glassware to shift or even break. The controlled motion of Hydraulic Buffer Hinges ensures that the contents remain secure, reducing the risk of damage and potential injury from broken items.

In industrial settings, Hydraulic Buffer Hinges are particularly valuable for their safety features. They are often used in heavy machinery and equipment where a sudden closure could lead to serious accidents or equipment malfunction. The controlled closing action of these hinges helps to maintain a safe operating environment, reducing the risk of injury to workers and the potential for costly repairs.

Furthermore, Hydraulic Buffer Hinges are designed to withstand the test of time, offering a high level of durability that contributes to their safety. They are made from robust materials that resist wear and tear, ensuring that the hinges continue to function effectively and safely over extended periods of use. This durability is crucial in maintaining the integrity of the hinge's safety features, as a hinge that is prone to failure can pose a significant risk.

In conclusion, Hydraulic Buffer Hinges offer a range of safety advantages that traditional hinges cannot match. Their controlled closing action, resistance to damage, and durability all contribute to a safer environment for users and the protection of the items they are used on. As a result, Hydraulic Buffer Hinges are becoming increasingly popular in a variety of applications where safety is a paramount concern. Their continued use in these settings is a testament to their effectiveness in enhancing safety standards and reducing the risk of accidents and injuries.

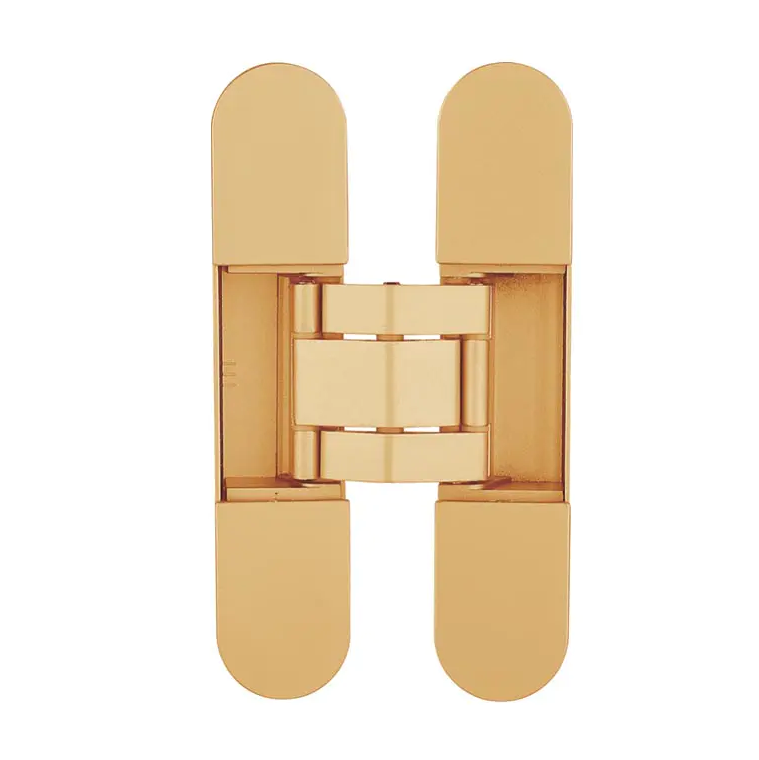

Product Advantages

1. Easy Installation:

By streamlining installation, this hinge enhances operational efficiency, enabling quicker setup times and reducing labor costs.

2. Smooth Operation:

Leveraging advanced hydraulic mechanisms, this hinge guarantees quiet and seamless door movements. This not only improves user comfort but also creates a more pleasant environment, particularly in residential settings.