When planning your industrial heat transfer system, one of the most critical decisions is choosing the right type of heat exchanger. Among the most widely used options are the Detachable Plate Heat Exchanger (also known as Gasketed Plate Heat Exchanger) and the Shell and Tube Heat Exchanger. While each has its strengths, if you're looking for maximum efficiency, compact design, and easy maintenance, the https://www.yojointernational.com/Gasketed-Plate-Heat-Exchanger/Gasketed-Plate-Heat-Exchanger-K150H.shtml is the solution that checks all the boxes.

What Is a Detachable Plate Heat Exchanger?

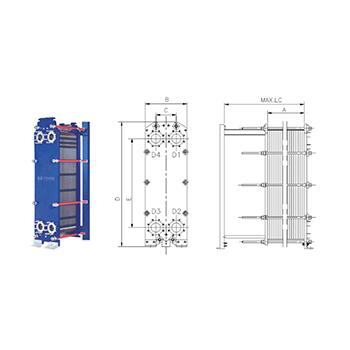

A Detachable Plate Heat Exchanger consists of a series of thin, corrugated metal plates clamped together in a frame. Gaskets between the plates direct the flow of hot and cold fluids into alternate channels, enabling effective heat exchange. The structure is fully accessible, making cleaning and servicing simple—ideal for industries with high hygiene and efficiency standards.

Why Choose the YOJO Gasketed Plate Heat Exchanger K150H?

1. Superior Heat Transfer Efficiency

Thanks to its optimized plate pattern and highly engineered flow channels, the YOJO detachable plate heat exchanger K150H offers an exceptionally high heat transfer coefficient. It enables efficient energy exchange even with a small temperature difference, making it ideal for energy-saving applications.

2. Compact and Space-Saving Design

Compared to traditional shell and tube exchangers, the detachable plate heat exchanger K150H offers the same—or even better—performance within a much smaller footprint. This space-saving design is perfect for facilities where installation space is limited, without compromising performance.

3. Easy Maintenance and Cleaning

The detachable design allows operators to open the unit easily for routine inspections, gasket replacements, or thorough cleaning. This reduces downtime and maintenance costs significantly—especially important in food processing, beverage, and pharmaceutical applications.

4. Flexible and Customizable

YOJO’s detachable plate heat exchanger K150H can be tailored to meet a wide range of process conditions. With various plate materials (such as stainless steel, titanium, and Hastelloy) and gasket options available, the unit can handle different fluids, temperatures, and pressure levels with ease.

5. Lower Operational Costs

The combination of high thermal efficiency and reduced pressure loss results in lower energy consumption. Additionally, the ease of maintenance and extended service life contribute to lower long-term operational costs.

When Might a Shell and Tube Heat Exchanger Be Used?

Shell and Tube Heat Exchangers are well-suited for applications with extremely high temperatures, pressures, or heavy-fouling fluids. While they are more robust in structure, they are also bulkier, more difficult to clean, and less efficient compared to plate-type heat exchangers in most standard industrial applications.

Which One Is Right for You?

If your project values:

A. High heat transfer performance

B. Space efficiency

C. Easy and frequent cleaning

D. Energy savings and reduced OPEX

Then the YOJO Gasketed Plate Heat Exchanger K150H is your ideal solution.

For processes involving extreme conditions or highly contaminated fluids, shell and tube units may be considered. However, for the majority of industries—from HVAC to food processing, from energy systems to chemical manufacturing—the plate heat exchanger outperforms in terms of flexibility, economy, and maintenance.

About YOJO

Jiangsu Yuanzhuo Equipment Manufacturing CO., LTD., also simply known as YOJO, is a trusted name in the heat exchanger industry. Our team of specialists brings together decades of experience in the field, mastering the most advanced technologies in the research, design, and manufacture of plate heat exchangers.

At YOJO, we are committed to delivering innovative, efficient, and customized thermal solutions to meet the evolving needs of global industries.