One of the most significant trends in plastic food container mould production is the shift towards eco-friendly materials. As concerns about plastic waste escalate, manufacturers are seeking ways to make food containers more sustainable. This has led to innovations in the use of recyclable plastics and bio-based materials, which can be incorporated into the design and production of food containers.

Plastic food container moulds, particularly those used to produce thin wall containers, are benefiting from these material advancements. For example, manufacturers are increasingly turning to recycled plastic in their injection moulding processes. By using recycled PET (rPET) and other sustainable materials, companies can help reduce the need for virgin plastic, which in turn lowers the overall environmental impact of the packaging. These materials not only meet the required safety standards for food contact but also contribute to a circular economy by promoting the reuse of plastics.

In addition, some companies are investing in bio-plastics, which are derived from renewable sources like cornstarch or sugarcane. While not yet as widespread as recycled plastics, bio-plastics offer the potential for reducing dependence on fossil fuels while still providing durable and functional packaging.

https://www.food-container-mold.com/product/disposable-plastic-square-food-container-moulds/square-product-mold.html

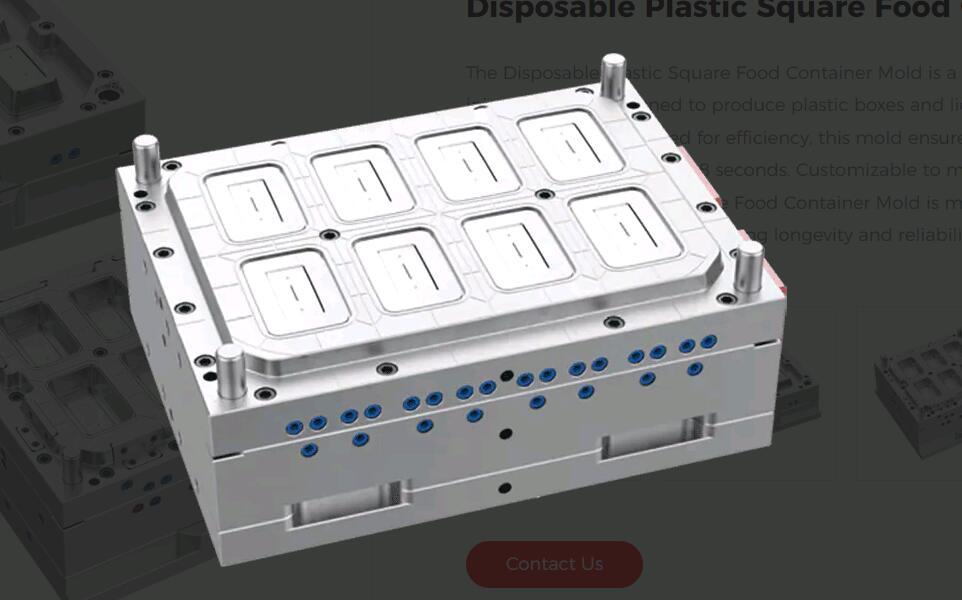

The Disposable Plastic Square Food Container Mold is a high-precision plastic injection mold designed to produce plastic boxes and lids with excellent sealing performance. Engineered for efficiency, this mold ensures a swift molding cycle of just 6 seconds or within 6-8 seconds. Customizable to meet specific requirements, the Disposable Plastic Square Food Container Mold is made from durable PP (polypropylene) material, ensuring longevity and reliability.