The use of Injection Color Masterbatch has become a preferred approach in the plastic industry for achieving consistent and efficient product coloring. Compared to other coloring methods, it offers several practical advantages that benefit both manufacturers and end-users.

One of the primary advantages is color consistency. Injection Color Masterbatch ensures uniform distribution of color throughout the plastic product. This minimizes the risk of streaks or shade differences, which can affect product appearance and quality control standards. Its pellet form makes it easier to handle and dose accurately during the injection molding process, reducing the likelihood of color variation.

Another notable advantage is process efficiency. Since the colorant is pre-dispersed in a compatible carrier resin, it integrates smoothly with base materials during molding. This simplifies production and reduces the preparation time often required when using powder or liquid pigments. Additionally, it allows for better control over coloring costs by preventing wastage and improving color yield per unit weight.

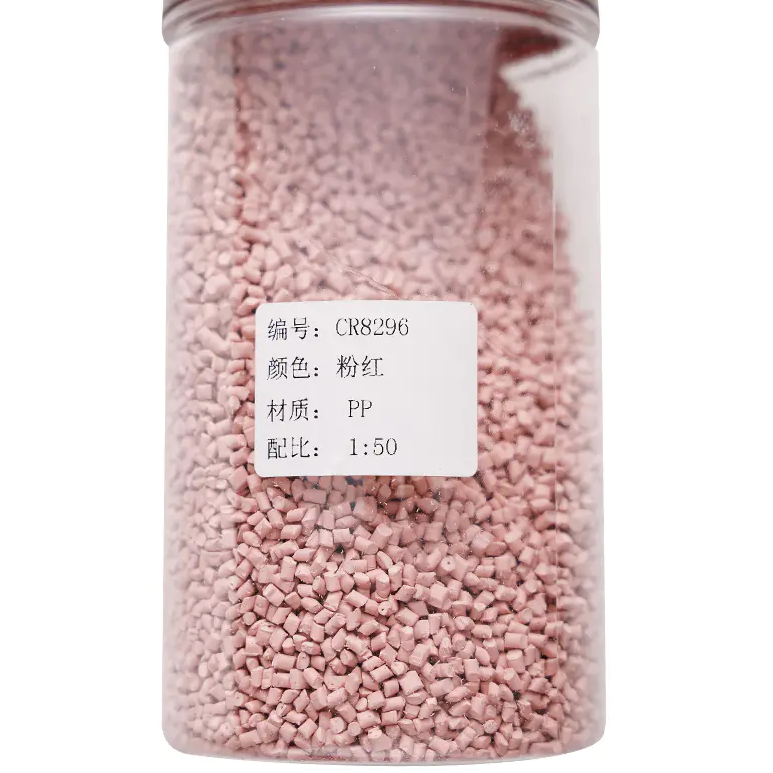

Injection Color Masterbatch also offers excellent compatibility with a wide range of polymers, including polyethylene, polypropylene, and polystyrene. This versatility enables manufacturers to use the same masterbatch formulation for multiple product lines, simplifying inventory management and production planning.

Moreover, it helps improve the environmental and operational cleanliness of production facilities. Unlike powders, which can create dust, the pellet form of masterbatch reduces contamination risks and promotes safer working conditions.

By combining color accuracy, ease of use, material compatibility, and clean processing, Injection Color Masterbatch offers manufacturers a dependable solution for producing consistent, high-quality plastic products.