An NdFeB magnets manufacturer plays a significant role in providing magnetic materials used across a wide range of industries. NdFeB magnets, also known as neodymium magnets, are recognized for their strong magnetic properties and compact size. These magnets are used in electronics, automotive, renewable energy, medical devices, and various other fields. Understanding the capabilities and services offered by an NdFeB magnets manufacturer can help businesses select the right partner for their specific requirements.

The manufacturing process of NdFeB magnets involves careful alloy formulation, powder production, pressing, sintering, and coating. An experienced NdFeB magnets manufacturer ensures that each step is conducted with precision to maintain magnet performance and durability. The magnetic strength, coercivity, and resistance to corrosion depend heavily on the quality control measures applied by the manufacturer.

Material sourcing is a crucial aspect for any NdFeB magnets manufacturer. Neodymium, iron, and boron are the key elements of these magnets. Consistent quality of raw materials influences the final magnet characteristics. Some manufacturers work closely with material suppliers to secure high-purity components, thereby reducing defects and improving magnetic properties.

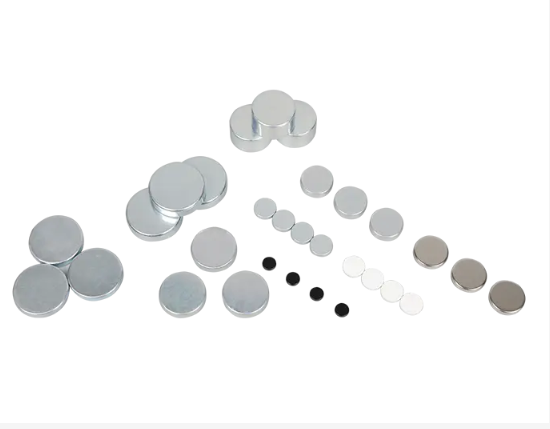

Customization is a service often provided by an NdFeB magnets manufacturer. Different applications may require magnets of various sizes, shapes, or magnetic strengths. Manufacturers may also offer additional treatments such as nickel, zinc, or epoxy coatings to protect the magnets from oxidation and physical wear. This flexibility allows clients to obtain magnets tailored to their specific technical needs.

Quality testing is another important responsibility for an NdFeB magnets manufacturer. This typically involves measuring magnetic properties, dimensional accuracy, and coating integrity. Adhering to industry standards or client specifications helps ensure that the magnets perform reliably in end-use applications. Testing also minimizes the risk of premature failure or performance loss.

In addition to manufacturing, some NdFeB magnets manufacturers provide technical support and consultation. This can be valuable for clients designing products that incorporate magnets, offering advice on magnet placement, strength requirements, and safety considerations. Such collaboration helps optimize the performance and cost-effectiveness of the final product.

Environmental and safety concerns are becoming more relevant in magnet manufacturing. Some NdFeB magnets manufacturers implement sustainable production practices and waste management to reduce their environmental impact. Safe handling and packaging of magnets are also emphasized due to their strong magnetic fields and brittle nature.

Logistics and timely delivery are crucial for many businesses relying on NdFeB magnets manufacturers. Efficient supply chain management allows manufacturers to meet demand and maintain production schedules. Clear communication between the manufacturer and client ensures that order specifications and timelines are understood.

An NdFeB magnets manufacturer provides essential components that contribute to the functionality of numerous modern devices and machines. By focusing on material quality, customization, testing, and customer service, the manufacturer supports the diverse needs of industries that depend on strong and reliable magnets.