In the modern power industry, aluminum alloy profiles are gradually becoming important materials in power infrastructure due to their advantages such as lightness, high strength and corrosion resistance. The application of aluminum alloy profiles not only enhances the operational efficiency of equipment but also reduces transportation and installation costs. Therefore, an in-depth exploration of the characteristics and applications of aluminium profiles for windows and doors will have significant guiding significance for the development of practitioners and enterprises in related industries.

I. Basic Concepts of aluminium profiles for windows and doors

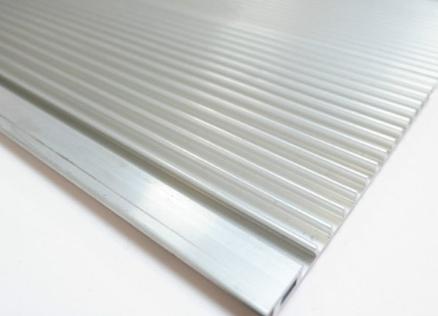

Aluminum alloy profiles are various types of profiles made from aluminum and other alloying elements (such as silicon, magnesium, zinc, etc.) through processes like smelting, casting, and extrusion. Due to the excellent physical and chemical properties of aluminum alloy itself, it has shone brightly in the power industry.

In the power industry, aluminum alloy profiles are typically used to manufacture transmission line towers, distribution boxes, switch cabinets, as well as the frames, brackets and protective shells of various electrical equipment. These profiles not only feature light weight and high strength, but also demonstrate excellent corrosion resistance, making them particularly suitable for long-term use in damp and highly polluted environments.

Ii. Advantages of aluminium profiles for windows and doors

1. Lightweight

The density of aluminium alloy is only one third that of steel, and it has excellent lightweight properties. This characteristic significantly reduces the labor intensity of aluminum alloy profiles during handling, transportation and installation, while also lowering transportation costs. Furthermore, lightweighting also means that when installing brackets and electrical appliances, the requirements for the load-bearing capacity of the infrastructure can be effectively reduced.

2. High strength

Although the strength of aluminum alloy profiles is lower than that of certain types of steel, after special treatment and alloy formulation, the tensile strength and compressive strength of aluminum alloy profiles have been significantly enhanced, which is sufficient to meet the usage requirements of most power equipment. Especially in high-voltage transmission lines, aluminum alloy profiles can withstand wind loads and snow loads under extreme weather conditions.

3. Corrosion resistance

Compared with traditional iron or plastic materials, the surface of aluminum alloy profiles can form a dense layer of aluminum oxide film, which has extremely strong corrosion resistance. Therefore, in coastal areas or other power facilities with complex environments, aluminum alloy profiles can better maintain the stability of their appearance and performance, achieving a longer service life.

4. Excellent electrical conductivity

In the power industry, electrical conductivity is an important performance index of materials. Aluminum alloy has struck a balance between high electrical conductivity and lightweight. In the components of power transmission lines, aluminum alloy profiles can not only serve as supporting structures but also as auxiliary materials for conductors.

Iii. Application Fields of aluminium profiles for windows and doors

Transmission line towers

Aluminum alloy profiles are widely used in the tower structures of high-voltage transmission lines. Due to the lightweight feature of aluminum alloy, transmission towers can reduce their own weight while ensuring strength and stability, thereby alleviating the burden on the foundation and reducing the investment in civil engineering.

2. Switch cabinets and distribution boxes

In power distribution equipment, aluminum alloy profiles are also used as the frame materials for switch cabinets and distribution boxes. Its corrosion resistance and excellent processing performance enable the switch cabinet to adapt to various harsh environments, and while ensuring safety, it is also convenient for cooling and heat dissipation.

3. Electrical equipment brackets

The electrical equipment brackets made of aluminum alloy profiles are not only lightweight and sturdy, but also can meet various installation forms through different processing methods, which is convenient for adapting to changes in equipment configuration and on-site conditions. This provides great convenience in the process of power generation and maintenance.

4. Substations and distribution networks

In the structure of substations and distribution networks, aluminum alloy profiles can be used to construct transformer frames, busbar supports and various grounding devices. Such applications can significantly improve the installation efficiency of the equipment and reduce the maintenance costs in the later stage at the same time.

Iv. Future Development Trends

From a global perspective, as the power industry continues to pursue new materials and technologies, the market demand and application of aluminum alloy profiles will keep growing. In the future, the following aspects may become new directions for the development of aluminum alloy profiles:

1. New alloy formula

Research and develop more advanced aluminum alloy formulas to endow aluminum alloy profiles with better strength, toughness and heat resistance, meeting higher requirements in high-pressure and high-temperature environments.

2. Innovation in surface treatment technology

Strengthen the research on surface treatment technology of aluminum alloy profiles to enhance their anti-rust and anti-corrosion performance. For instance, it might be envisaged to adopt nano-coating technology to further enhance the surface wear resistance and heat resistance.

3. Recycling and reuse

Environmental protection and sustainable development have become a global consensus. In the production and application of aluminium profiles for windows and doors, more and more attention will be paid to the recycling and reuse of materials. This can not only reduce material costs, but also minimize resource waste and achieve the goal of a circular economy.

4. Applications of intelligent manufacturing

Relying on emerging technologies such as the Internet of Things and artificial intelligence, the intelligent production and management of aluminium profiles for windows and doors are realized, improving production efficiency and product quality. At the same time, it also brings more efficient solutions to the power industry.

Conclusion

To sum up, aluminium profiles for windows and doors play an indispensable role in the modern power industry. Its diverse application scenarios and unique performance advantages have demonstrated the significance of aluminum alloy profiles in enhancing the safety and economy of power infrastructure. With the development of technology and the increasing demand in the industry, the future of aluminum alloy profiles will be brighter and they will surely lead the new trend in the power industry at that time.

aluminium profiles for windows and doors https://www.rongxinhao.com/Door-and-window-profiles.html