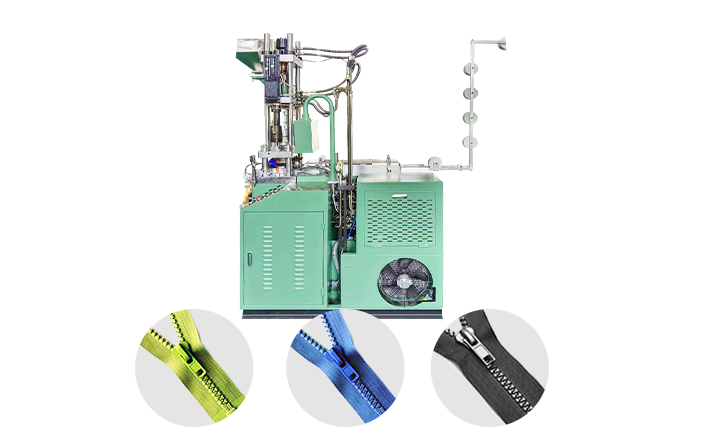

The resin zipper machine has revolutionized the zipper production industry by providing a highly efficient and automated solution for manufacturing durable resin zippers. This cutting-edge machine is designed to streamline the entire molding process, offering significant improvements in both speed and precision. By using advanced technology, the resin zipper machine ensures high-quality results that meet the rigorous demands of modern manufacturing.

One of the standout features of the resin zipper machine is its ability to automatically inject resin into zipper molds, producing a smooth and uniform finish. This automated process not only reduces labor costs but also minimizes the risk of human error, ensuring that every zipper is consistently made to the highest standard. The machine's precision allows for the production of zippers that are not only durable but also flexible, making them ideal for a wide range of applications, including clothing, bags, and outdoor gear.

In addition to its efficiency, the resin zipper machine is designed for ease of operation. With user-friendly controls and customizable settings, operators can quickly adjust the machine to meet specific production needs. This versatility makes it a valuable asset for manufacturers looking to scale their operations while maintaining top-notch quality. Furthermore, the machine's high throughput ensures that production deadlines are met without sacrificing performance or quality.

Overall, the resin zipper machine is a game-changing piece of equipment that enhances productivity, reduces costs, and improves the overall quality of zippers. As the demand for high-performance zippers continues to grow, this machine stands out as an indispensable tool for manufacturers looking to stay ahead of the competition.