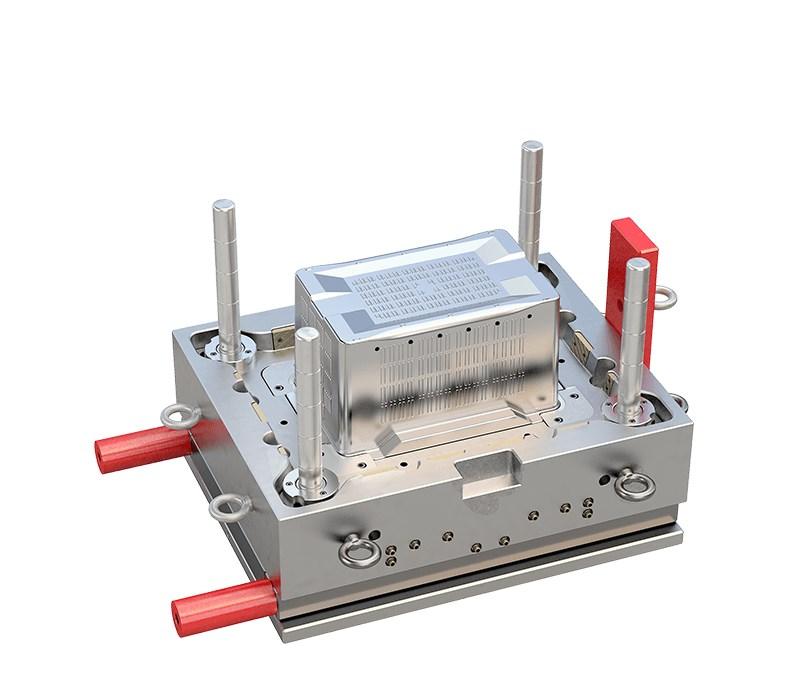

The manufacturing process of the Plastic Industrial Box Mould is a delicate balance of art and science, where temperature control plays a pivotal role in determining the quality and efficiency of the final product. The molds, which are designed to produce a variety of plastic boxes for industrial applications, require precise temperature management to ensure optimal performance and longevity.

Temperature control in the context of Plastic Industrial Box Moulds is not merely about maintaining a constant heat; it is about understanding the thermal dynamics of the materials involved and the intricate relationship between heat and the molding process. The temperature of the mold directly affects the flow of the plastic material, the cooling rate, and the overall quality of the finished product.

To begin with, the initial stage of the process involves preheating the Plastic Industrial Box Mould to a specific temperature. This preheating is essential to ensure that the mold is at an optimal temperature for the injection of the plastic material. The temperature must be carefully calibrated to match the melting point of the plastic being used, allowing for a smooth and even flow of the material into the mold cavities.

Once the Plastic Industrial Box Mould reaches the desired temperature, the injection phase begins. During this phase, the plastic material, typically in the form of pellets or granules, is heated to a molten state and injected into the mold under high pressure. The temperature of the mold must be carefully monitored and maintained to ensure that the plastic material cools and solidifies uniformly, preventing defects such as warping, shrinkage, or uneven wall thickness.

In addition to the initial temperature setting, the cooling phase is equally critical in the manufacturing process of Plastic Industrial Box Moulds. The mold must be cooled down to a temperature that allows for the plastic to solidify without causing internal stresses or distortions. This cooling process is typically facilitated by the use of cooling channels within the mold, which circulate a coolant to dissipate heat effectively.

The use of advanced temperature control systems, such as hot runner systems, is also prevalent in the manufacturing of Plastic Industrial Box Moulds. These systems maintain a constant temperature in the mold's runner system, ensuring a consistent flow of material and reducing the occurrence of defects due to temperature fluctuations.

Moreover, the selection of materials for the Plastic Industrial Box Mould itself is crucial in temperature management. High-quality steel alloys with excellent thermal conductivity and heat resistance are often chosen to withstand the rigors of the molding process and to facilitate efficient heat transfer.

In conclusion, temperature control in the manufacturing process of Plastic Industrial Box Moulds is a multifaceted challenge that requires a deep understanding of the materials, the molding process, and the thermal dynamics involved. By implementing precise temperature management strategies, manufacturers can ensure the production of high-quality, durable, and consistent Plastic Industrial Box Moulds that meet the demands of various industrial applications. The integration of advanced temperature control technologies and the selection of appropriate materials further enhance the efficiency and effectiveness of the molding process, solidifying the importance of temperature control in the realm of Plastic Industrial Box Mould manufacturing.