Auto parts mold plays a crucial role in the manufacturing of automotive components, ensuring precision, durability, and functionality. The process involves creating molds from high-quality materials to shape metal or plastic parts used in vehicles. These molds are essential for producing parts with consistent dimensions and properties, which is critical for vehicle performance and safety.

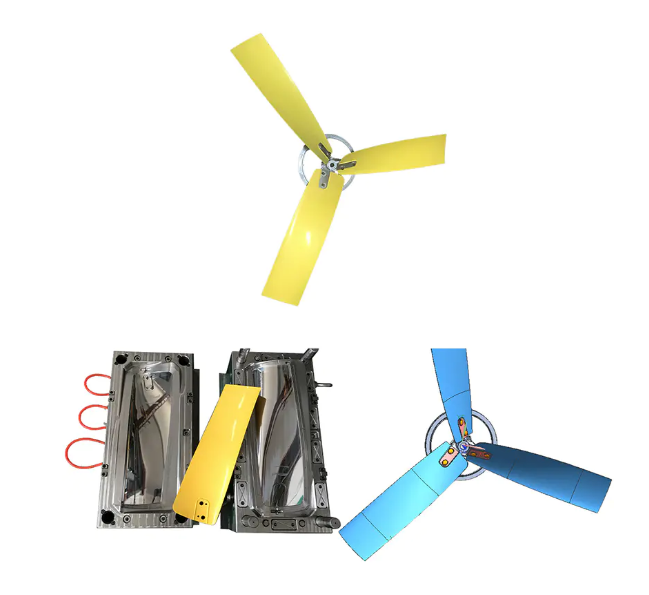

The mold-making process begins with designing a prototype of the part, followed by creating a detailed mold from materials such as steel or aluminum. Advanced techniques like Computer Numerical Control (CNC) machining and injection molding are often used to achieve high precision. Once the mold is prepared, it undergoes rigorous testing to ensure it meets the required specifications.

A well-designed mold reduces the likelihood of defects and increases production efficiency. For instance, precision molds ensure that each component fits perfectly during assembly, which is vital for complex automotive systems. Additionally, high-quality molds enhance the longevity of auto parts by reducing wear and tear.

As the automotive industry continues to evolve with advancements in technology, the importance of high-quality molds cannot be overstated. They are integral to producing reliable and high-performance vehicles, contributing to overall road safety and driving experience.

In summary, auto parts mold is fundamental to the automotive manufacturing process. Investing in advanced mold technology ensures precision, durability, and efficiency, ultimately benefiting both manufacturers and consumers.