Auto parts moulds are critical in the production of high-quality, reliable vehicle components. From exterior body panels to mechanical parts, these moulds form the foundation for creating pieces that are both functional and aesthetically appealing. An auto parts mould factory is responsible for designing, manufacturing, and testing these moulds, which requires a deep understanding of both the automotive industry and advanced moulding technologies.

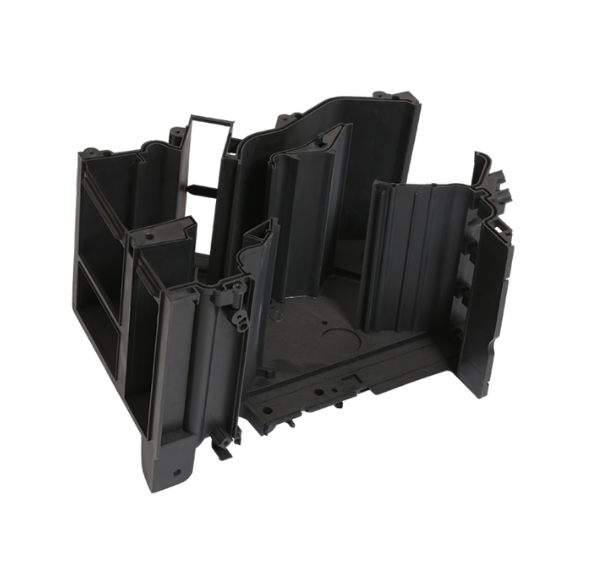

The manufacturing process of auto parts begins with creating precise moulds that are capable of producing a variety of car parts. This includes everything from structural components to decorative trim. Advanced moulding techniques such as injection moulding and die casting are commonly used to create components with the required shape, strength, and appearance.

Durability is one of the most important considerations when designing auto parts moulds. Since automotive components must withstand a range of environmental conditions—such as extreme temperatures, mechanical stress, and exposure to chemicals—the moulds used must be made from durable materials. High-strength metals such as steel are commonly used for the production of these moulds, as they can endure the pressures of moulding and the demands of automotive applications.

Additionally, the efficiency of an auto parts mould factory directly impacts the overall production of vehicles. High-quality moulds help streamline the manufacturing process, ensuring that components are produced quickly and accurately. This reduces the risk of delays in the vehicle production cycle, helping to keep costs down while maintaining high standards of safety and quality.