The performance of the ABS embossed logo can be influenced by the color in which they are produced, and understanding these differences is essential for companies looking to maintain a consistent brand image across various applications. ABS, or Acrylonitrile Butadiene Styrene, is a versatile thermoplastic polymer known for its strength, durability, and ease of processing. When it comes to the production of ABS embossed logos, the choice of color can affect several aspects of their performance, including visibility, resistance to fading, and overall aesthetic appeal.

Color plays a significant role in the perception of quality and can influence consumer behavior. Bright and vibrant colors can make an ABS embossed logo stand out, while darker shades may provide a more subtle and sophisticated look. However, the choice of color is not just about aesthetics; it also impacts the durability and longevity of the logo. For instance, lighter colors may show signs of wear and tear more readily than darker ones, as scratches and dirt are more visible on lighter surfaces. This can be particularly important for logos that are subjected to frequent handling or are used in outdoor settings where they are exposed to the elements.

The process of coloring ABS embossed logos involves the use of pigments and dyes that are mixed with the polymer during the manufacturing process. These colorants can affect the physical properties of the ABS, such as its flexibility and resistance to UV radiation. Some colors may be more prone to fading under prolonged exposure to sunlight, which can lead to a loss of vibrancy and a dull appearance over time. This is particularly relevant for outdoor applications where the ABS embossed logos are constantly exposed to UV rays. In such cases, the choice of color and the quality of the colorants used can significantly impact the longevity of the logo.

Additionally, the color of an ABS embossed logo can influence its thermal stability. Darker colors tend to absorb more heat, which can lead to a higher risk of deformation or damage when the logo is exposed to high temperatures. This is an important consideration for applications where the logos are used in environments with fluctuating temperatures, such as automotive parts or outdoor signage.

The choice of color also has implications for the environmental impact of ABS embossed logos. Some colorants used in the production process may contain heavy metals or other harmful substances that can be released into the environment during disposal or recycling. As a result, the color selection can contribute to the overall eco-friendliness of the product. Companies that prioritize sustainability may choose to use colors that are produced with environmentally friendly pigments and dyes to minimize their environmental footprint.

In conclusion, the performance of ABS embossed logos in different colors is a multifaceted issue that encompasses aesthetic appeal, durability, thermal stability, and environmental impact. By understanding how color affects these various aspects, companies can make informed decisions when selecting the colors for their ABS embossed logos. This ensures that the logos not only look good but also perform well in their intended applications, while also aligning with the company's sustainability goals.

https://www.labels-factory.com/product/plastic-label/abs-3d-badge/

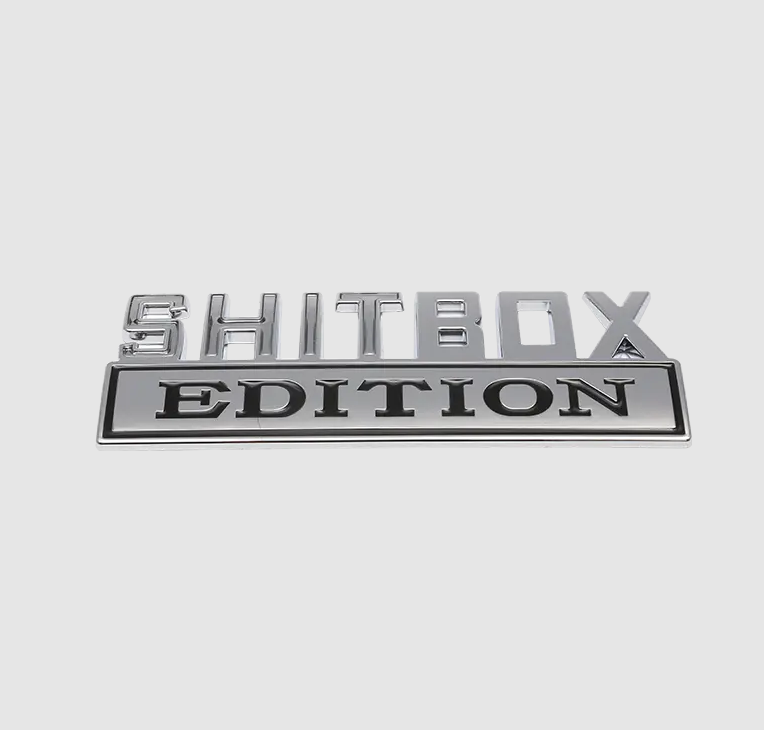

Material: Plastic ABS

Thickness: 1.0-5.0mm usually

MOQ: 100pcs, 500pcs, all depends on customer's request, small orders accepted

Size and shape: Custom-made, oval, rectangle, square, round, irregular shape ok

Colors: Customized colors, Pantone Matching System

Printing: Silkscreen printing, digital printing

Fixing: Strong permanent adhesive, 3M adhesive tape on the back

Drawing format: AI, PDF, CorelDraw, EPS, PSD, Hi-res PDF