The front bumper molding is a critical component of modern vehicle design, serving both aesthetic and functional purposes.

The early days of automobiles saw the front bumper as a basic metal bar, primarily for protection against minor collisions. However, as vehicle design evolved, so did the role of the front bumper. It became more than just a protective barrier; it was an integral part of the vehicle's overall design and safety system.

Over time, materials used for front bumper molding have seen significant advancements. Early bumpers were made from heavy steel, which, while durable, added unnecessary weight to vehicles and was not energy-absorbing. The development of plastics and composite materials allowed for lighter, more flexible bumpers that could absorb impact energy more effectively, reducing damage to both the vehicle and pedestrians.

As consumer preferences shifted towards sleeker, more streamlined vehicles, the design of front bumper moldings became more sophisticated. Designers began to integrate bumpers seamlessly into the vehicle's overall aesthetic, using them to enhance the car's look rather than detract from it. This focus on design not only improved the visual appeal of vehicles but also contributed to better aerodynamics.

The most significant development in front bumper molding has been in the area of safety. Modern bumpers are designed to absorb and distribute impact energy, reducing the risk of injury to passengers and pedestrians. Features such as crumple zones and energy-absorbing materials have become standard, making vehicles safer in the event of a collision.

With growing environmental awareness, the development of front bumper molding has also taken into account sustainability. Materials are now chosen not only for their performance but also for their recyclability and low environmental impact. This shift towards eco-friendly materials reflects the industry's commitment to reducing its carbon footprint.

https://www.bumpermould.net/product/bumper-mould/2016-audi-a5-front-rear-bumper-mould.html

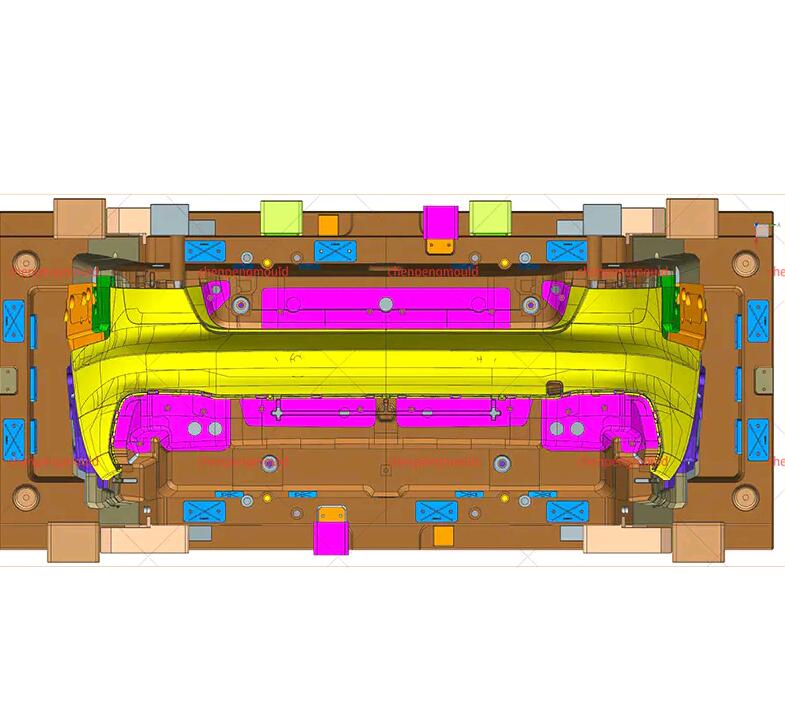

Mould Name Audi A5 Car Bumper Mould

Material PP+EPDM(Contraction: 1, 5%)

Bumper Size 1800*510*460mm

Steel For Cavity &. Core P20

Mould Base C45

NOs. of Cavity 1*1

Injection System Yudo 5 direct injection gates

Ejection System Ejector pins, angle lifters