The effectiveness of Tapered Drilling Tools largely depends on their taper angle, which influences performance in different drilling applications. Understanding how taper angles affect drilling efficiency can help professionals select the right tools for specific tasks.

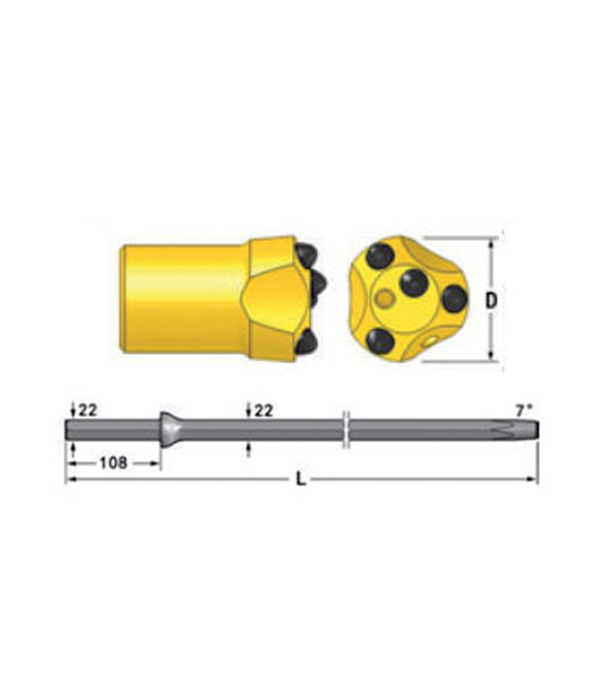

Taper angles typically range from 7 to 12 degrees, with each angle offering distinct advantages. A smaller taper angle provides a stronger connection between the rod and the bit, making it suitable for hard rock formations. On the other hand, a larger taper angle allows for quicker bit changes, improving efficiency in softer rock conditions.

Choosing the correct taper angle for tapered drilling tools is crucial for achieving smooth and precise drilling. Using an inappropriate angle can result in reduced drilling speed, excessive wear on the bit, or unstable operation. Proper matching of the drill bit and rod enhances the overall performance and longevity of the tool.

Regular maintenance and correct handling further contribute to the durability of tapered drilling tools. Ensuring that the taper connection remains intact and free of debris helps maintain efficiency in drilling operations.

By understanding the role of taper angles, professionals can make informed decisions when selecting tapered drilling tools. This knowledge allows for better drilling results while minimizing equipment wear and operational costs.

https://www.kqdrill.com/product/tapered-bits/7-degree-tapered-drilling-tools-6.html

1. High fatigue strength and toughness.

2. The crushing ability is strong, the rock drilling speed is fast, and it is convenient for grinding.

Application: Mines, tunnels, water conservancy