In the intricate world of electronics, the stability of signal transmission is of utmost importance, and Board to Board Power Connectors play a critical role in this regard. These connectors are responsible for establishing a reliable connection between two or more printed circuit boards, ensuring that power and signals are transmitted without interruption. The question of how much the stability of signal transmission is influenced by Board to Board Power Connectors is a multifaceted one, involving factors such as design, materials, manufacturing processes, and environmental conditions.

The stability of signal transmission is directly related to the quality of the connection provided by the Board to Board Power Connectors. A well-designed connector will have a robust mechanical structure that ensures a secure and consistent contact between the mating surfaces, which is essential for maintaining signal integrity. Any looseness or misalignment can lead to intermittent connections, resulting in signal loss or distortion. Therefore, the precision engineering of Board to Board Power Connectors is crucial for minimizing these issues and ensuring stable signal transmission.

Materials used in the construction of Board to Board Power Connectors also have a significant impact on signal stability. High-quality materials can resist corrosion, which is particularly important in environments where connectors are exposed to moisture or other corrosive elements. Corrosion can lead to increased contact resistance and signal degradation over time. Additionally, the choice of material can affect the connector's ability to dissipate heat, which is another factor that can influence signal stability, especially in high-power applications.

Manufacturing processes play a vital role in determining the performance of Board to Board Power Connectors. Advanced manufacturing techniques can ensure that the connectors are produced with tight tolerances and uniform characteristics, which contribute to consistent performance across the board. Any deviations in the manufacturing process can lead to variability in the connectors, which in turn can affect signal transmission stability.

Environmental conditions are another factor that can impact the performance of Board to Board Power Connectors. Connectors that are subjected to extreme temperatures, high humidity, or mechanical stress can experience changes in their physical properties, which can lead to degraded signal transmission. Therefore, understanding the operating environment and designing connectors that can withstand these conditions is essential for maintaining signal stability.

In conclusion, the influence of Board to Board Power Connectors on signal transmission stability is substantial. The design, material selection, manufacturing process, and environmental conditions of the connectors will affect the signal stability. The connector must be able to provide a stable and reliable connection to ensure lossless transmission of signals between circuit boards. Any design defects, material deficiencies, errors in the manufacturing process or adverse effects of environmental factors may lead to instability in signal transmission. Therefore, to ensure the performance and reliability of electronic equipment, it is crucial to conduct in-depth research and optimization on the design and performance of Board-to-Board Power Connectors.

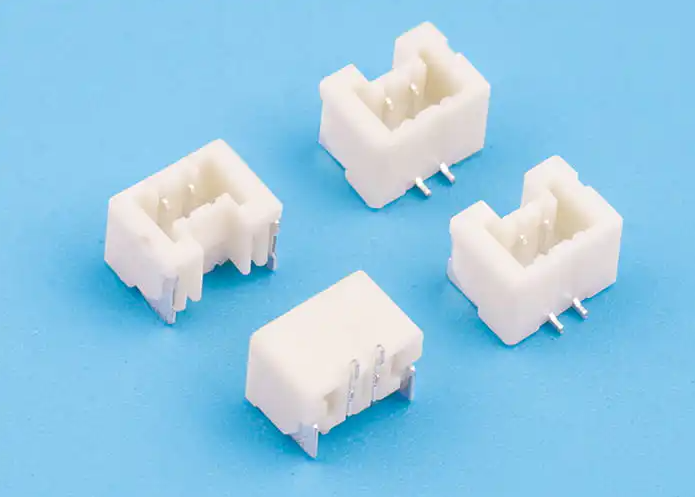

1、CKT: 2Pin

2、Current rating: 1A AC/DC

3、Voltage rating(max): 125V, AC/DC

4、Working Temperature: -25°C~+85°C,

(Including temperature rise in applying electrical current)

5、Contact resistance: value s20mΩ

After environmental testing≤30msΩ

6、Insulation resistance: 2100MΩ

7、Withstand voltage: 500VAC(rms)

8、Applicable PCB board thickness: 1.6mm to 2.0mm