Precision in mould design and manufacturing ensures uniformity in the bucket caps produced. Caps that fit consistently and seal effectively are crucial for applications where airtightness, leak prevention, or contamination resistance is required.

Accurate moulding ensures even material distribution, enhancing the structural integrity of the caps. This durability is especially important in applications where caps must withstand physical stress, temperature fluctuations, or chemical exposure.

Precise moulding guarantees that bucket caps meet exact specifications for their intended use. For instance, caps designed for food-grade buckets must fit snugly to preserve freshness and comply with regulatory standards.

High precision reduces defects and minimizes material waste during production. This not only lowers costs but also supports sustainable manufacturing practices.

The materials used to manufacture the bucket cap mould play a significant role in its precision and longevity. Commonly used materials include hardened steel and high-grade aluminum, which provide the necessary strength and wear resistance.

Computer-aided design (CAD) and computer-aided manufacturing (CAM) software allow engineers to create highly detailed mould designs. These tools enable simulations to identify and rectify potential issues before the mould is produced.

Precision machining equipment, such as CNC (computer numerical control) machines, is essential for crafting intricate mould components with tight tolerances. These machines ensure that the mould’s dimensions are accurate to within micrometers.

https://www.ysmou.com/product/cap-mould/plastic-injection-bucket-cap-mould-with-antitheft-ring.html

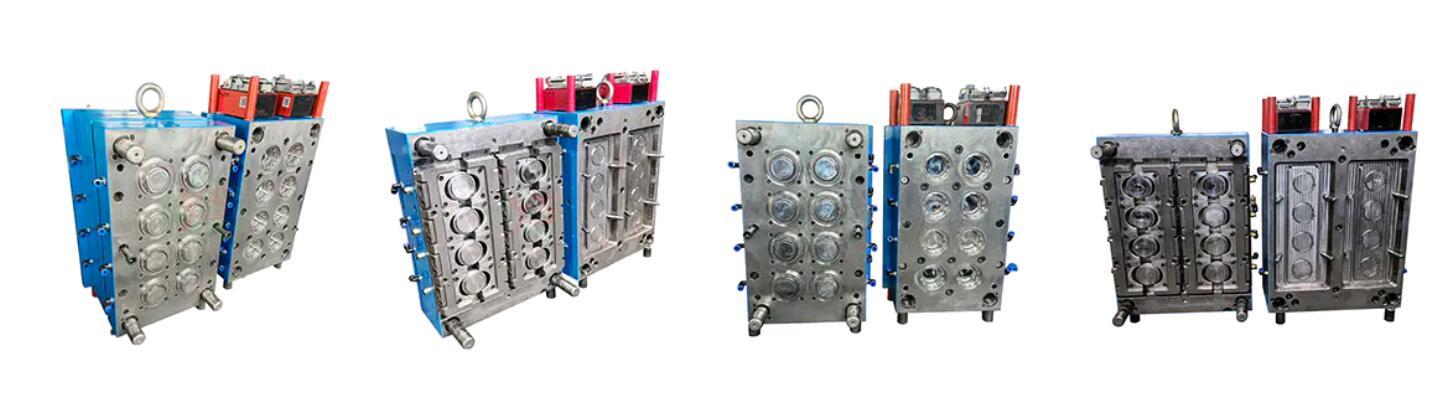

This type of mould is assembled from outer cap and an inner anti-theft ring. The outer cap is automatically rotated and pushed out by a hydraulic motor, requiring manual installation without much effort.

During the processing, we strictly control each step and test to ensure product quality and delivery time. After each sample is confirmed by the customer for quality, it is arranged for shipment.