From a manufacturer’s point of view, producing baguette pans involves careful selection of materials, design considerations, and precise manufacturing processes. Baguette pans are specialized bakeware designed to support the unique shape and baking needs of baguettes, requiring both functionality and durability.

Material choice is one of the main factors in manufacturing baguette pans. Commonly, manufacturers use aluminum, carbon steel, or aluminized steel due to their good heat conductivity and resistance to warping. These materials help ensure even baking, which is important for achieving consistent crust and crumb texture. Among these, carbon steel is often preferred for its balance of strength and heat retention properties.

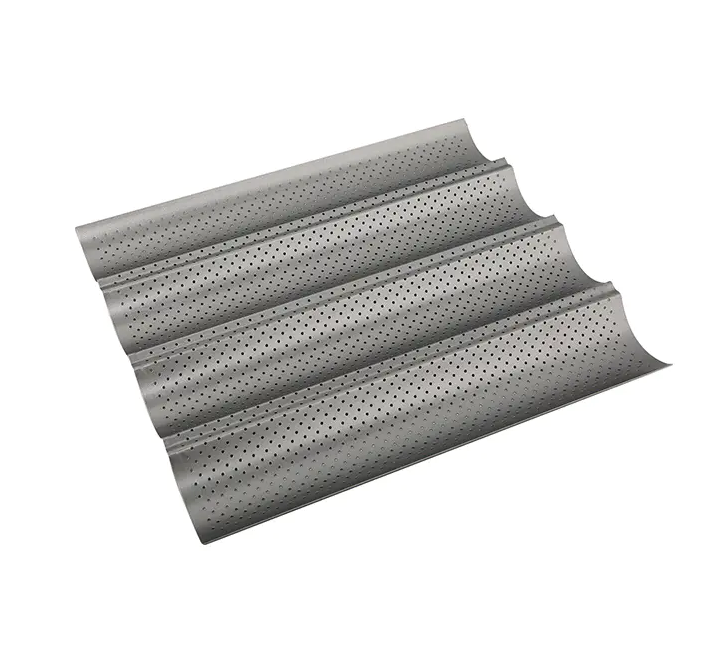

The production process begins with cutting sheets of metal into the correct size. Precision in cutting is important to reduce waste and ensure that each pan maintains uniform dimensions. After cutting, the metal is formed into baguette-shaped molds, usually through a pressing or stamping process. This shaping needs to be accurate to create the elongated grooves that hold the dough in place and give baguettes their characteristic form.

Surface treatment is also a significant part of production. To prevent sticking and to facilitate easy release of the baked bread, manufacturers commonly apply non-stick coatings. These coatings require careful application to ensure even coverage and durability. Some manufacturers also offer uncoated options that require seasoning before use, which can appeal to traditional baking methods.

Reinforcement of edges and structural stability are other aspects considered during manufacturing. The edges of the pan are typically rolled or folded to increase strength and to protect users from sharp edges. Additionally, the pan must be sturdy enough to withstand repeated heating and handling in both commercial and home bakery settings.

Quality assurance plays a vital role in the manufacturing process. Manufacturers inspect pans for consistent dimensions, smooth surfaces, and proper coating application. This helps in maintaining product reliability and baking performance. Testing for heat distribution and resistance to warping is sometimes performed to ensure the pan meets practical baking requirements.

Packaging is designed to protect the pans during shipping and storage. Many manufacturers use custom inserts or sturdy boxes that minimize movement and potential damage. Clear labeling and instructions are also included to inform users about care and use.

Environmental concerns influence manufacturing choices as well. Some producers focus on minimizing waste and using recyclable materials in their packaging. Additionally, efforts to reduce energy consumption during production can be part of sustainable manufacturing strategies.

Customization options are often provided to meet different customer needs. This can include variations in pan size, number of baguette slots, coating types, and color finishes. Manufacturers may also adjust designs to fit specific oven sizes or to accommodate baking techniques preferred in different regions.

In summary, manufacturing baguette pans requires a combination of suitable materials, precise shaping, surface finishing, and quality control. These elements contribute to producing pans that support consistent baking results and meet the needs of bakers across various settings.