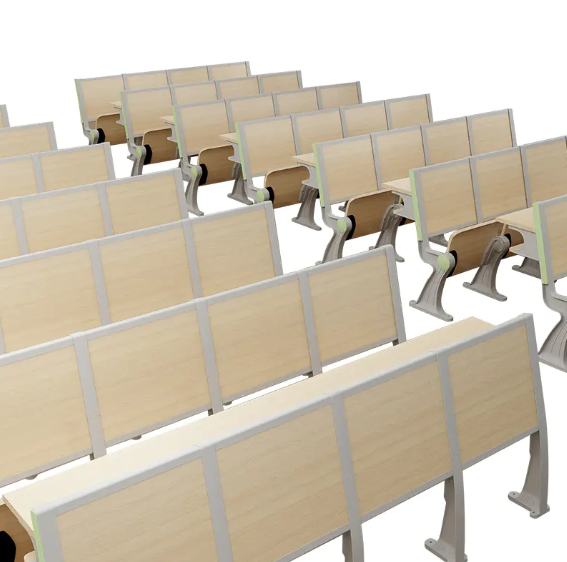

The lecture hall table and chair are fundamental components in educational furniture, widely used in universities, colleges, and large training facilities. While their usage in classrooms is widely understood, fewer people are familiar with the complex process behind their production. From material selection to quality assurance, each stage in the manufacturing of lecture hall table and chair units involves careful planning to meet the demands of institutional environments.

One of the first steps in the production process is the selection of raw materials. A lecture hall table and chair must be built using materials that offer structural integrity and long-term reliability. Manufacturers often rely on powder-coated steel for the frame due to its resistance to corrosion and ability to handle frequent use. The tabletops and chair backs are commonly made from high-pressure laminate, molded plywood, or durable plastic, selected for their ease of maintenance and resistance to wear.

Precision engineering plays a key role during the fabrication stage. The components of a lecture hall table and chair set—frames, tabletops, and seat structures—must be cut and assembled with accuracy to ensure consistency across mass production. CNC (computer numerical control) machines are frequently used to cut metal and wood parts to exact dimensions, allowing seamless assembly and a uniform appearance.

Welding and joint stability are crucial elements, particularly for integrated table-chair systems. The lecture hall table and chair units are often fixed in long rows, which requires strong joints to withstand frequent use over time. During production, welds are checked for strength and consistency, and joints are reinforced at stress points to minimize the risk of structural failure.

Once the primary structure is built, surface finishing begins. This step includes painting metal parts with scratch-resistant coatings and applying laminate to wood or plastic surfaces. Each lecture hall table and chair must be finished in a way that balances visual appeal with practicality. Manufacturers also take into account the safety aspects of edges and corners, which are often rounded or protected to prevent accidents.

Before shipping, quality control ensures that every lecture hall table and chair meets functional and visual standards. This process includes weight testing, visual inspection, and stability checks. For larger orders, some manufacturers provide assembly demonstrations or offer modular systems that can be easily put together on-site.

Environmental considerations are becoming more common in the production process. Many factories now use low-emission adhesives and recyclable materials in the construction of lecture hall table and chair units. This approach supports sustainable practices without compromising durability.

Manufacturers may also provide customization options. Based on the client's preferences, the lecture hall table and chair design can be modified in terms of color, seat size, folding features, or additional components like book racks and power modules. This flexibility helps institutions equip their learning spaces in a way that aligns with architectural layouts and user requirements.

Producing a reliable lecture hall table and chair set involves much more than simply assembling parts. It requires thoughtful design, careful material sourcing, precision machinery, and rigorous testing. These factors together contribute to a product that can handle the demands of daily academic use while maintaining a professional appearance.