Modern pharmaceutical production lines rely heavily on automation for filling, sealing, and packaging prefilled syringes. Rubber stoppers manufacturer are engineered to be compatible with automated equipment, enabling consistent placement, reliable sealing, and efficient assembly without compromising product integrity.

The stoppers’ dimensional stability and uniformity reduce risks of manufacturing defects such as incomplete seals or stopper deformation.

Sterilization Compatibility: Butyl rubber stoppers must withstand common sterilization methods, including gamma irradiation and ethylene oxide (EtO) sterilization, without degradation.

Storage Conditions: While durable, these stoppers should be stored under controlled temperature and humidity to maintain their mechanical properties and prevent premature aging.

Customization: Stoppers can be tailored in terms of size, shape, and surface treatments to match specific syringe designs and formulation requirements.

Understanding the detailed characteristics and performance of butyl rubber stoppers enables pharmaceutical manufacturers and healthcare providers to select reliable sealing solutions that meet regulatory standards and optimize syringe performance. With continued advancements in materials science and manufacturing processes, butyl rubber stoppers will remain a trusted choice in the evolving landscape of injectable medical devices.

https://www.klstopper.com/product/medical-rubber-products-series/disposable-blood-collection-needle-sheath.html

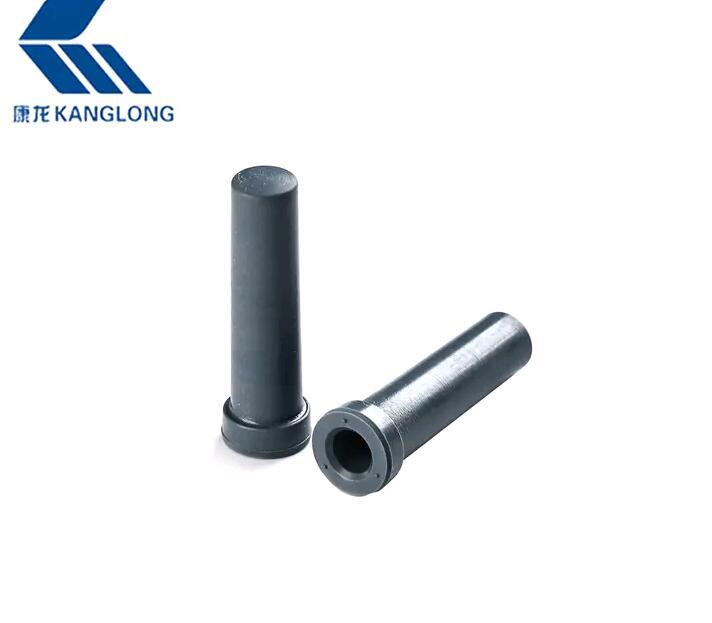

Disposable Blood Collection Needle Sheath

Uses: The product is installed on a disposable blood collection needle and can continuously work during the blood collection

Packing: Inner Packing Is Sterilizabled Bags, Outer Packing Is Carton

Enterprise Standard: YY/T0313-2014