In the modern electronics industry, where devices are increasingly compact, mobile, and expected to operate in rugged environments, the WTB Wire to Board Connector plays a critical role in maintaining reliable electrical connections between wire assemblies and printed circuit boards (PCBs). One of the most crucial performance parameters for these connectors is their ability to withstand vibration and mechanical shock without failure, signal interruption, or degradation in electrical performance. This article explores how the WTB Wire to Board Connector is designed and tested to meet the demanding requirements of vibration and shock resistance in various applications.

The environments in which WTB Wire to Board Connectors are used—such as automotive electronics, industrial control systems, home appliances, and consumer electronics—often expose them to continuous vibration, frequent mechanical movement, or occasional but severe shocks. For example, in an automotive application, connectors must endure the vibrations from engine operation, road irregularities, and impacts during driving. If the connection between the wire and PCB becomes unstable, even momentarily, it could lead to critical failures such as signal loss, intermittent power issues, or complete system shutdowns.

To address these challenges, manufacturers have engineered WTB Wire to Board Connectors with enhanced mechanical locking mechanisms that prevent the connector from disengaging under dynamic stress. Locking latches, friction fits, and terminal retention features ensure that the mated components stay securely connected even in high-vibration conditions. Additionally, the materials used in these connectors—often high-performance plastics and corrosion-resistant metals—are selected for their mechanical durability, fatigue resistance, and thermal stability, which contribute to vibration resilience over long service lifetimes.

Another essential design aspect is the contact geometry. The contacts within a high-quality WTB connector are typically spring-loaded or shaped to provide consistent pressure, which helps maintain a secure electrical connection even as the components vibrate. This reduces the risk of micro-movements that can cause wear or fretting corrosion over time, a common failure mode in dynamic environments.

Manufacturers also conduct rigorous mechanical testing to verify the connector’s shock and vibration performance. These tests often conform to international standards such as IEC 60068 or MIL-STD-202, involving subjecting the connector to controlled mechanical pulses and sinusoidal vibrations across various frequencies and amplitudes. Successful testing ensures that the WTB Wire to Board Connector can withstand real-world mechanical stresses without contact failure or physical damage.

Furthermore, designers often use strain relief features and proper cable management techniques in conjunction with the connector to reduce stress on the termination points. This integrated approach extends the mechanical life of the connector system as a whole.

In conclusion, the WTB Wire to Board Connector is a highly reliable interface solution specifically engineered to perform under vibration and shock conditions commonly encountered in many modern applications. Through robust design, high-quality materials, and strict testing protocols, it offers the mechanical resilience necessary to maintain stable and long-lasting electrical connections, even in the harshest operational environments.

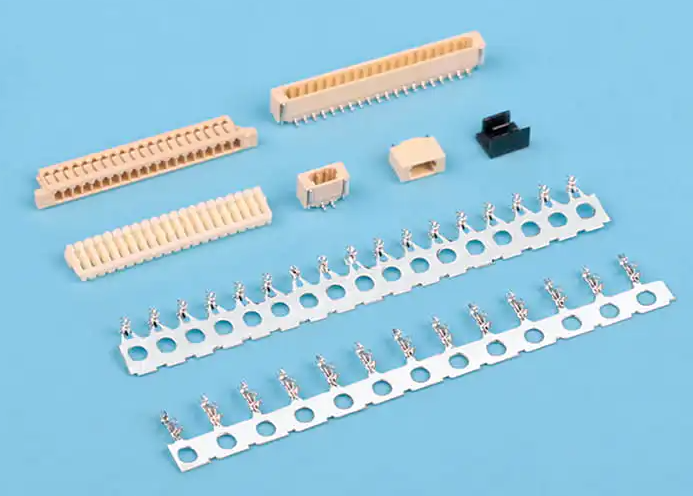

1、CKT: 2Pin to 25Pin

2、Current rating: 0.5A AC/DC

3、Voltage rating(max): 30V, AC/DC

4、Working Temperature: -25°C~+85C,

(Including temperature rise in applying electrical current)

5、Contact resistance: Initial value s20mΩ

After environmental testing≤40mΩ

6、Insulation resistance: 2100MΩ

7、Withstand voltage: 200VAC(rms)

8、Applicable wire: AWG #32 to #28

9、Applicable PCB board thickness: 1.6mm to 2.0mm