Automatic transparent film wrapping machine find applications across diverse industries:

Food Industry: Wrapping bakery items, fresh produce, frozen foods, and confectionery to maintain freshness and hygiene.

Pharmaceuticals: Securing medicines and medical devices to ensure tamper evidence and contamination prevention.

Consumer Electronics: Protecting devices and components from dust and scratches during shipping.

Retail Goods: Bundling multiple products for promotional packaging or multipacks.

The machine’s adaptability to various product sizes and shapes makes it suitable for packaging irregularly shaped items as well as uniform products.

Maintenance and Operational Considerations

To ensure optimal performance, regular maintenance is essential. This includes cleaning the sealing jaws, checking tension rollers, lubricating moving parts, and inspecting electrical components. Proper training of operators on machine settings and troubleshooting further enhances reliability and extends the machine’s service life.

Manufacturers often provide technical support and upgrade options, allowing users to keep pace with evolving packaging demands.

By understanding the core characteristics and performance advantages of these machines, businesses can make informed decisions about investing in packaging technologies that improve operational efficiency and product presentation. As market demands for quality and efficiency continue to grow, automatic transparent film wrapping machines remain a valuable asset in the packaging toolkit.

https://www.zjjwjx.cn/product/cellophane-wrapping-machine/jw-260b-fully-automatic-transparent-film-wrapping-machine.html

Packing speed Single box film per minute(20~100)

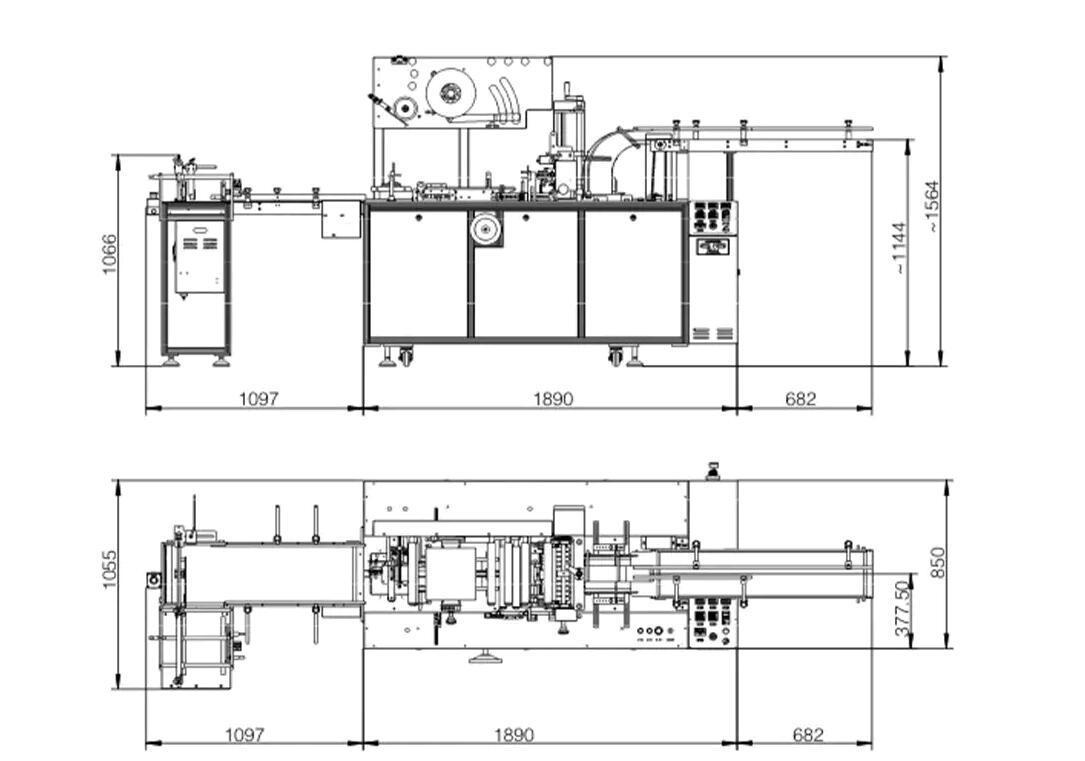

Package size L(30~200) W(20~120) H(8~50)mm

Input power Three-phase three-wire 220V 50Hz

Design total power 6.75kw

Heat sealing temperature 110-180℃