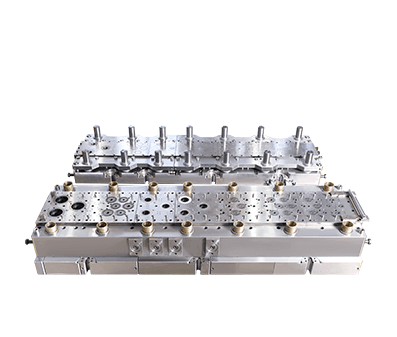

When it comes to consistent high-performance production, durability and operational reliability are essential—and the high speed stamping mold delivers on both fronts. Engineered with premium materials and advanced treatment techniques, this mold is built to withstand the rigors of high-speed, high-volume manufacturing.

The high speed stamping mold is constructed using high-grade tool steels known for their excellent hardness, toughness, and resistance to wear. Through specialized surface treatments such as nitriding and quenching, the mold’s components gain enhanced surface strength and longevity. These processes ensure that the mold maintains its dimensional stability and cutting sharpness even after millions of cycles, significantly extending its service life and reducing maintenance frequency.

In addition to its rugged construction, the high speed stamping mold features a highly efficient chip removal and lubrication system. Designed with optimized waste discharge channels, the mold prevents clogging and ensures that trimmed materials are expelled smoothly during operation. This minimizes downtime caused by material buildup or jamming and helps maintain continuous, high-speed production.

Furthermore, integrated lubrication pathways within the high speed stamping mold ensure that all critical moving parts receive consistent lubrication, reducing friction and wear. This not only enhances the life of the mold but also supports smoother and quieter operation, essential in high-precision environments.

The synergy of durability and clean operation allows the high speed stamping mold to perform at peak efficiency with minimal interruptions. Manufacturers can depend on it for stable output, reduced tooling costs, and fewer production halts—all of which contribute to improved profitability.

In summary, the high speed stamping mold is more than just a tool—it's a long-term production asset. With its superior wear resistance and well-engineered waste/lubrication systems, it sets a new standard for reliable, high-speed stamping performance.