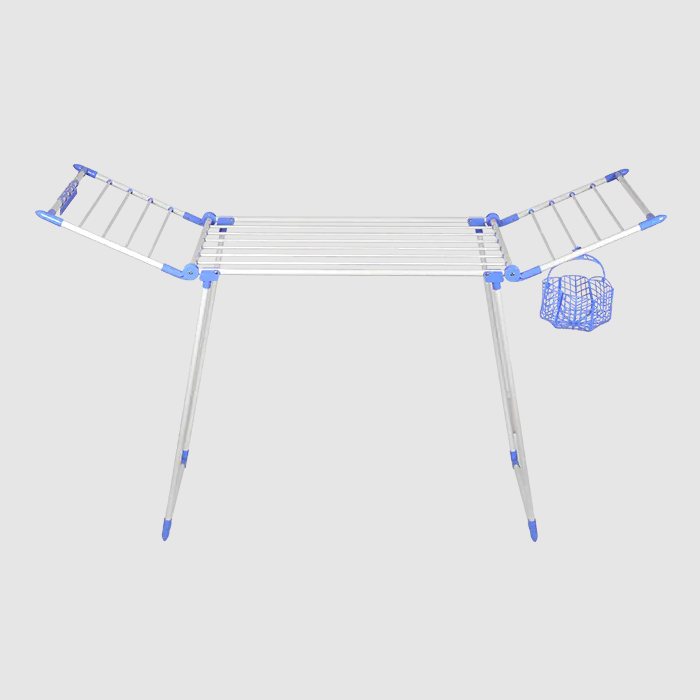

From a manufacturing perspective, producing a wing drying rack involves a focus on durability, functionality, and user convenience. The selection of materials plays a critical role; manufacturers often choose corrosion-resistant metals or alloys to ensure the rack can withstand moisture and frequent use without degradation.

Precision in the manufacturing process is essential for the folding mechanism. The hinges and joints that allow the wings to open and close must be engineered to operate smoothly and reliably over many cycles. Quality control checks are typically implemented to ensure these moving parts meet performance standards and provide a consistent user experience.

Surface treatment is another important manufacturing step. Powder coating or other protective finishes help guard against rust and scratches, extending the lifespan of the drying rack. This finish also contributes to the rack’s aesthetic appeal by providing a uniform and clean look.

Assembly procedures are designed for efficiency, often involving modular components that can be easily put together or replaced if needed. This approach helps keep production costs manageable while maintaining product quality.

Manufacturers also consider the overall design to balance maximum drying space with compactness when folded. Ergonomic factors, such as the height and spacing of rods, are optimized to suit common user needs and improve drying effectiveness.

Testing is a vital part of manufacturing, ensuring the rack supports the weight of wet laundry without bending or losing stability. Durability tests simulate repeated use to verify long-term performance.

In conclusion, manufacturing a wing drying rack requires attention to material selection, mechanical design, surface treatment, and quality control. These factors combine to produce a reliable and user-friendly product suitable for diverse drying applications.