Quarry operations depend on reliable tools that can handle repeated impact and abrasive materials. The Top Hammer Drill Bit is widely used for bench drilling in stone quarries, thanks to its capability to break through dense materials quickly and consistently.

Pairing this with Extension Drilling Tools offers flexibility in reaching varied depths without the need for equipment relocation. This results in reduced downtime and increased efficiency across operations.

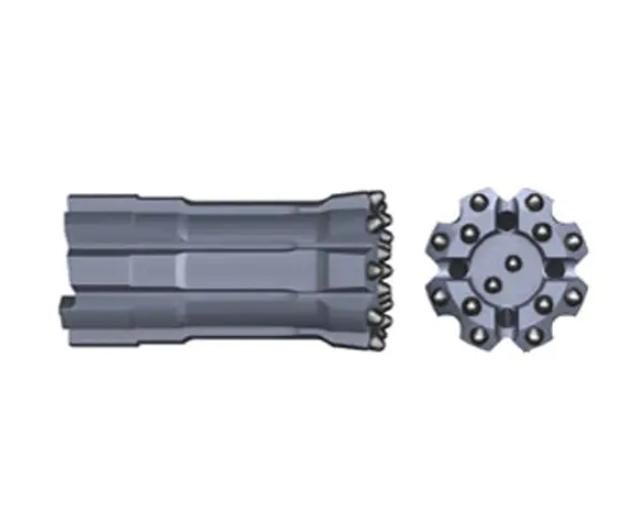

Operators often work with different rock formations, and choosing the correct bit design—button or cross-type—can influence drilling performance. When combined with robust extension rods, the hammer system ensures better energy delivery and less wear per meter drilled.

Quarry teams benefit from lightweight extension rods that still offer sufficient tensile strength to handle harsh vibrations. These rods can be replaced or adjusted as needed, keeping operations fluid and adaptable to different project phases.

By standardizing tool combinations and conducting regular inspections, quarry managers can extend tool lifespans and reduce costs over time. Using dependable components like the Top Hammer Drill Bit with suitable Extension Drilling Tools supports consistent and predictable results.