Custom sanding discs play a significant role in a wide range of industrial and DIY surface preparation tasks. From metal polishing to woodworking and automotive finishing, these discs are widely used to achieve smooth, clean, and uniform surfaces. Unlike standard discs, custom options allow users to select specific features such as grit size, backing material, and hole configuration to match their project requirements more accurately.

One of the main advantages of using custom sanding discs is the ability to tailor them to different machines and applications. Depending on the type of sanding tool—such as orbital sanders, disc sanders, or angle grinders—the disc shape and mounting system can vary. Customization ensures proper fit and secure attachment, which is essential for consistent results and safety during operation.

Material choice is another key aspect when selecting custom sanding discs. Manufacturers offer a variety of abrasive materials like aluminum oxide, zirconia alumina, ceramic, and silicon carbide. Each material performs differently based on the surface being treated. For example, aluminum oxide is often used for wood and soft metals, while ceramic grains work well on hardened steel. A custom disc allows users to choose the right combination of material and grit level for their specific needs.

The backing of custom sanding discs is equally important. Common options include paper, cloth, and film, each offering different levels of flexibility and durability. Some applications may benefit from a strong, tear-resistant backing, while others require more flexible discs that can conform to curved surfaces. Selecting the right backing through customization can enhance both the efficiency and finish quality of sanding work.

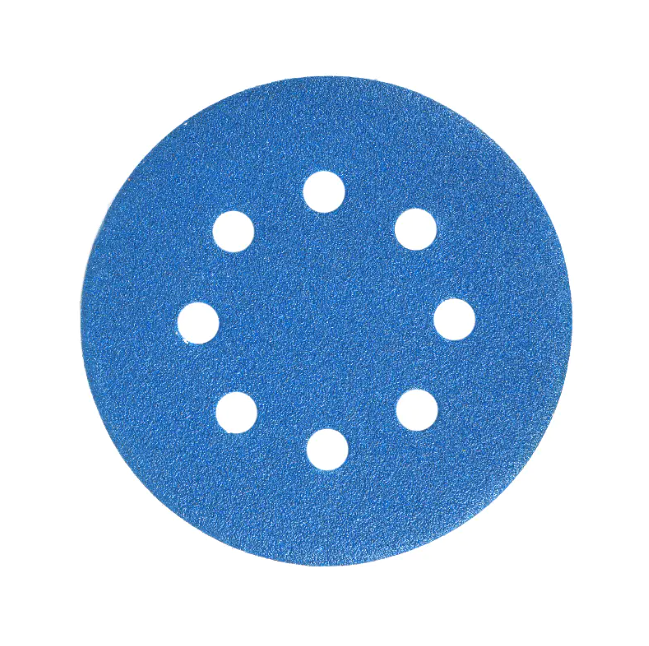

Hole patterns in custom sanding discs are often designed to improve dust extraction. Good airflow reduces heat and prevents clogging, which can extend the life of the disc. In dust-sensitive environments or for longer sanding sessions, a well-designed hole layout can significantly affect user comfort and productivity.

In many industries, having access to custom sanding discs also means improved material cost control. Instead of relying on standard sizes or types that may not match a specific process, businesses can reduce waste and enhance performance with discs that are manufactured to precise requirements. This flexibility supports industries like furniture manufacturing, automotive repair, and metal fabrication.

When ordering from suppliers, customers often specify grit size, abrasive type, diameter, backing material, hole layout, and adhesive system (hook-and-loop or PSA). This level of control allows them to develop a product line suited to their unique sanding challenges.

Custom sanding discs offer practical benefits in both specialized and everyday applications. By allowing users to choose the features that match their sanding equipment and surface materials, these discs provide greater flexibility and value. Whether for professional workshops or home-based projects, selecting the right disc configuration can lead to more consistent finishes and efficient workflows.