A sunshade fabric manufacturer plays a vital role in supplying materials that provide protection from sunlight while enhancing the appearance and function of outdoor spaces. These fabrics are commonly used in awnings, umbrellas, pergolas, canopies, and other shade systems for residential, commercial, and recreational settings. Choosing the right sunshade fabric manufacturer is an important decision for businesses involved in outdoor furnishings, architecture, or construction.

A professional sunshade fabric manufacturer typically offers a range of materials designed to withstand UV exposure, heat, moisture, and wear. Common materials include polyester, acrylic, and PVC-coated fabrics, which are treated to resist fading and mildew. These technical features are important for maintaining long-term durability and color consistency in various climate conditions.

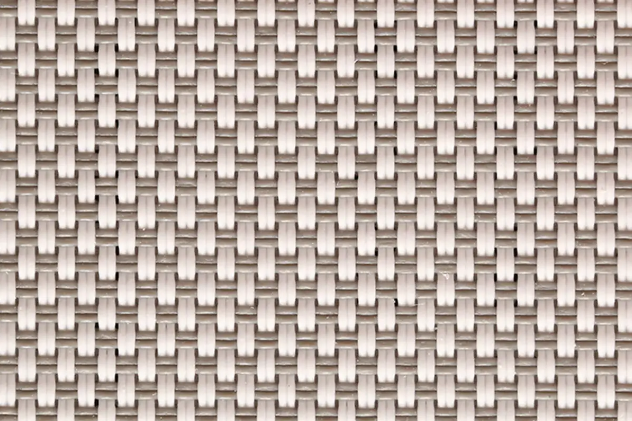

Customization is one of the major advantages of working with a sunshade fabric manufacturer. Clients often require specific colors, patterns, or textures to match their design goals. Whether for branding, aesthetics, or functionality, manufacturers may offer printing, coating, or patterning services. The ability to tailor fabric properties such as weight, breathability, and reflectivity allows buyers to meet project-specific requirements more effectively.

A well-established sunshade fabric manufacturer also considers environmental factors in the production process. Increasingly, there is demand for eco-conscious fabrics that are recyclable or made with reduced energy and water consumption. Some manufacturers provide certification or testing data that reflects their commitment to sustainability and compliance with international safety standards.

Consistency in product quality is critical. A reliable sunshade fabric manufacturer will follow quality control protocols to ensure that materials meet required tensile strength, colorfastness, and UV resistance standards. These factors help reduce the risk of premature wear or performance issues once the fabric is installed in its end-use environment.

Delivery timelines and production capacity are also important considerations. Whether supplying rolls of fabric or pre-cut panels, a sunshade fabric manufacturer must meet order quantities and deadlines. Especially during seasonal demand periods, the ability to produce and ship efficiently can make a difference in project planning and fulfillment.

In addition, manufacturers may support clients with technical resources. This includes fabric specifications, installation guidelines, and performance data. Such support is valuable for contractors, designers, and distributors who need accurate information to make informed purchasing and application decisions.

A sunshade fabric manufacturer is a key supplier for businesses that focus on outdoor solutions. From material quality and customization to sustainable options and delivery reliability, several factors influence the selection of a manufacturing partner. Collaborating with a capable sunshade fabric manufacturer ensures access to fabrics that perform well and meet aesthetic expectations across a variety of applications.