The cutting accuracy of a Horizontal Band Saw Machine is a critical aspect that directly impacts the quality and precision of the final workpiece. Maintaining consistent and precise cuts is essential for meeting production standards, reducing material waste, and improving overall operational efficiency. Several factors contribute to how a Horizontal Band Saw Machine can guarantee high cutting precision, from the mechanical design and blade selection to operational controls and maintenance practices.

At the core, the mechanical structure of the Horizontal Band Saw Machine plays a fundamental role in ensuring cutting accuracy. A rigid and stable frame minimizes vibrations and deflections during the cutting process, which can otherwise cause deviations in the cut line. Manufacturers invest in high-quality materials and robust construction techniques to reduce any unwanted movement or flex in the saw arm, blade guides, and workpiece clamping components. Precision-ground guides and adjustable blade tensioners help keep the saw blade running true and straight, preventing wandering or bowing that would degrade accuracy.

The saw blade itself is another crucial factor. The blade must be selected according to the material type, thickness, and desired finish. Blades with appropriate tooth pitch, width, and hardness ensure smooth cutting and reduce blade deflection under load. Regular inspection and timely replacement of worn or damaged blades are essential, as a dull blade tends to wander or produce rough cuts. Proper blade tensioning is equally important; too loose, and the blade will vibrate; too tight, and it risks breaking or causing excessive wear on bearings and guides.

Operational parameters also affect cutting precision. The feed rate and cutting speed must be optimized for the specific material and blade combination to avoid excessive force on the blade, which can cause deflection and inaccurate cuts. Modern Horizontal Band Saw Machines often incorporate variable speed drives and programmable feed controls, allowing operators to fine-tune cutting conditions. These features enhance the machine's adaptability to different jobs and contribute significantly to repeatable accuracy.

Workpiece holding and positioning are equally critical. A Horizontal Band Saw Machine must securely clamp the material to prevent movement during cutting. Precise positioning mechanisms, such as stops or digital readouts, help operators set exact cut lengths. Some machines are equipped with automated feeding systems and CNC controls that ensure consistent material placement and reduce human error. Proper alignment between the blade and the workpiece is necessary to avoid angled or uneven cuts.

Maintenance routines are vital for sustaining cutting accuracy over time. Regular lubrication of moving parts, checking blade guides and bearings for wear, and calibration of mechanical components prevent degradation in performance. Scheduled inspections and adjustments maintain the saw’s precision and extend its service life.

In summary, the cutting accuracy of a Horizontal Band Saw Machine is guaranteed through a combination of sturdy mechanical design, correct blade selection and maintenance, optimized operational settings, secure workpiece clamping, and consistent machine upkeep. By addressing each of these elements, manufacturers and operators can ensure that their Horizontal Band Saw Machine produces precise, reliable, and high-quality cuts that meet demanding production requirements.

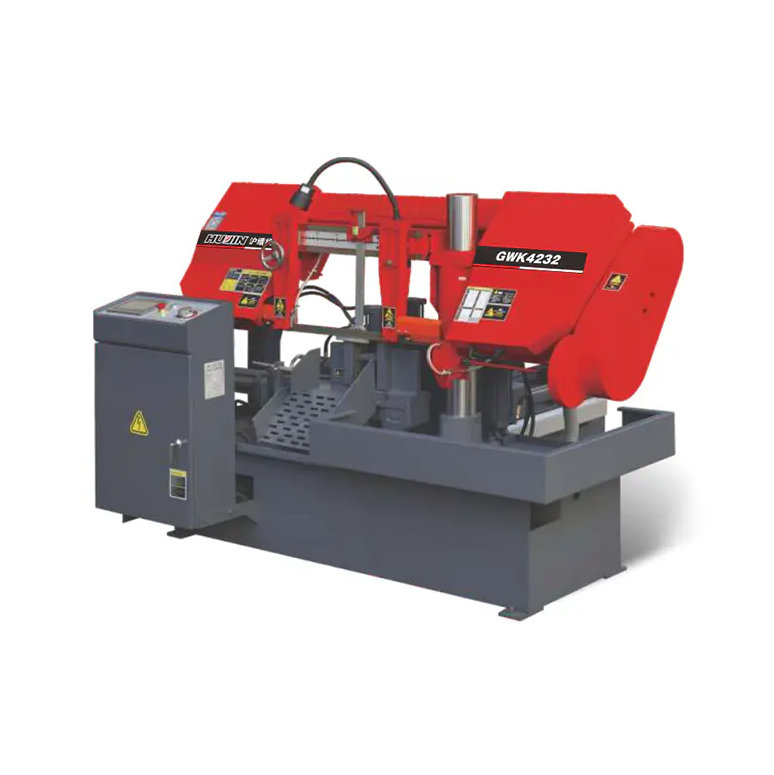

Cutting Capacity(mm):Round material Φ500/Plate 500x500

Blade speed(m/min):30,60,80

Blade Size(mm):1.3*41*6200

Single feeding travel(mm):500

Motor main output(kw): 4-6

Hydraulic(kw):1.5

Coolant pump(kw):0.09

Machine Size(LxWxH)(mm):3000*2200*1950