The temperature resistance of an FFC Ribbon Cable is a crucial consideration for designers and engineers who rely on its flexibility and compact form factor in modern electronic assemblies. This type of cable, known for its flat and lightweight structure, is widely used in devices such as laptops, printers, cameras, and automotive systems, all of which may encounter a variety of thermal conditions. The ability of the cable to perform reliably under different temperature ranges can significantly affect both the stability and safety of the entire system. FFC Ribbon Cable typically consists of multiple flat conductors encased in a thin insulating film, commonly made from materials like polyester (PET), polyimide (PI), or other engineered polymers. Each of these materials offers a different level of thermal resistance. Polyester-based cables are often suitable for applications with a temperature range up to about 80°C to 105°C. These are cost-effective and sufficient for most standard consumer electronics. However, for environments where temperatures exceed this range, polyimide-based cables are preferred due to their much higher tolerance, often capable of withstanding continuous exposure to temperatures up to 200°C or more. This makes them ideal for demanding industrial or automotive applications where heat exposure is frequent or prolonged.

The performance of an FFC Ribbon Cable under thermal stress is not only determined by the insulating material but also by the adhesive layer that bonds the conductors to the film. At elevated temperatures, adhesives can degrade, causing delamination, reduced electrical insulation, or mechanical failure. High-quality cables are designed with thermally stable adhesives that maintain integrity even under fluctuating or extreme heat. In addition to high-temperature resistance, it is equally important for these cables to perform in low-temperature environments, such as in aerospace electronics or outdoor equipment exposed to cold climates. Many FFC Ribbon Cables can function effectively down to -20°C or even lower, depending on the specific material composition. Flexibility at low temperatures is essential to prevent cracking or stiffness that could impair signal transmission or cause mechanical damage.

Another aspect of thermal performance is the effect of temperature on the cable's electrical characteristics. As temperature increases, so does the resistance of the copper conductors, which can result in power losses or signal degradation in sensitive circuits. For this reason, temperature ratings are typically accompanied by performance curves or derating information, guiding users in selecting the right cable based on their thermal profile. Long-term exposure to elevated temperatures, even within the stated limits, can accelerate aging of the insulation material and reduce the cable's overall lifespan.

Proper installation and heat management can also enhance the thermal performance of FFC Ribbon Cable. Routing the cable away from heat-generating components, ensuring proper ventilation, and using thermal shielding when necessary can help maintain a stable operating environment. In mission-critical systems, choosing a cable with higher thermal margins than the expected ambient conditions provides an added level of safety and reliability.

In conclusion, the temperature resistance of FFC Ribbon Cable depends heavily on its insulation material, adhesive properties, and intended application. While standard PET-based versions serve well in moderate conditions, polyimide variants offer enhanced durability for high-temperature or high-reliability environments. Understanding the thermal limitations and planning accordingly ensures optimal performance, extended service life, and reduced risk of thermal failure across a wide range of applications.

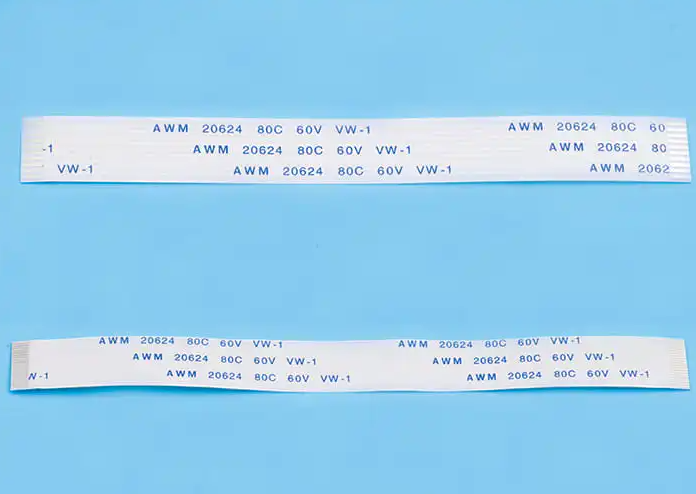

Product Feature:

High-quality flexible flat cable - FFC ribbon cable, standard pitch, multiple pin counts, reliable data connection, durable flat ribbon conductors