The pressure resistance of a high pressure pump is a critical attribute that determines its performance, safety, and longevity in demanding industrial environments. Ensuring that a high pressure pump can reliably withstand the extreme pressures it encounters during operation involves careful design, selection of materials, and rigorous testing procedures. Manufacturers and users alike must understand the mechanisms and features that contribute to maintaining high-pressure resistance.

One fundamental aspect of guaranteeing pressure resistance is the use of high-quality, robust materials in the pump’s construction. Components such as the pump casing, valves, seals, and pistons must be made from metals or alloys that can endure high stress without deforming or cracking. Common materials include stainless steel, hardened alloys, and sometimes ceramics for specialized parts. These materials are chosen not only for their mechanical strength but also for their resistance to corrosion and wear, which can weaken the pump over time.

The design of the high pressure pump also plays a pivotal role in its pressure resistance. Engineers carefully optimize the geometry and thickness of the pump housing to distribute stresses evenly and avoid weak points where failure might initiate. Reinforcements such as ribs or thicker walls are incorporated in areas exposed to the highest pressures. Moreover, precision machining ensures tight tolerances and proper fitting of components, which reduces the risk of leaks or pressure loss.

Sealing technology is another essential factor in preserving pressure resistance. High pressure pumps operate under conditions where even minor leaks can lead to significant efficiency losses or safety hazards. Therefore, advanced sealing solutions, including mechanical seals, lip seals, or specialized gasket materials, are employed to prevent fluid escape. These seals must maintain integrity under varying temperatures and pressures, which requires careful material selection and design.

Testing and quality control are indispensable in confirming that a high pressure pump meets the required pressure resistance standards. Before reaching customers, pumps typically undergo hydrostatic testing, where they are subjected to pressures exceeding normal operating levels to verify structural integrity and sealing performance. Non-destructive testing methods, such as ultrasonic or radiographic inspection, help detect any internal flaws or weaknesses that might compromise pressure resistance.

In operation, maintaining the pressure resistance of a high pressure pump also depends on proper installation and regular maintenance. Correct alignment and secure mounting prevent undue mechanical stresses that could weaken the pump structure. Scheduled inspections and timely replacement of worn components, especially seals and valves, help sustain pressure endurance over time.

In conclusion, the pressure resistance of a high pressure pump is ensured through a combination of selecting durable materials, employing sound engineering design, utilizing effective sealing technologies, and conducting comprehensive testing. Proper maintenance and operation further extend the pump’s ability to withstand high pressures reliably. Understanding these factors is vital for industries relying on high pressure pumps to operate safely and efficiently in demanding conditions.

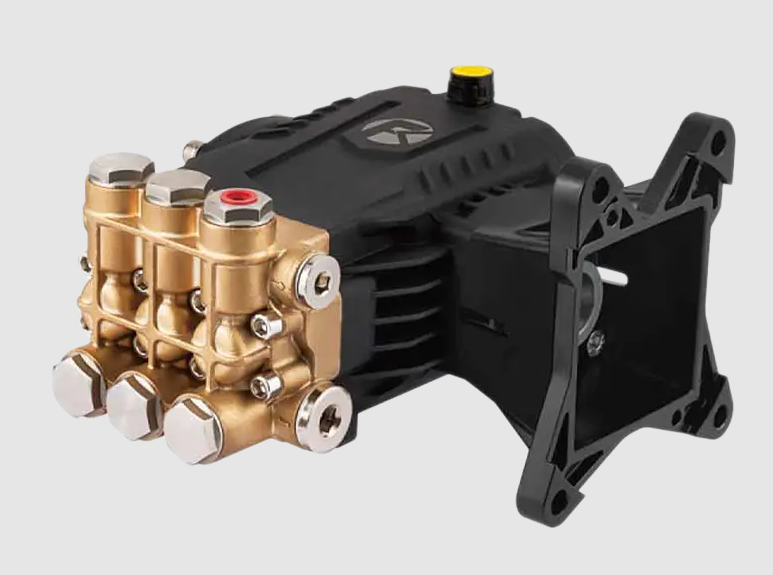

High Pressure Pump Product Description:

FKE-F04.1450rpm C Version Ø24mm