A pressure roll factory plays a crucial role in the production of various industrial rolls used in different sectors such as paper manufacturing, textile production, and packaging. These pressure rolls are essential components in a wide range of machinery, as they are designed to provide consistent pressure to the material being processed. By using high-quality materials and precise engineering, a pressure roll factory ensures that the rolls meet the specific requirements for each application.

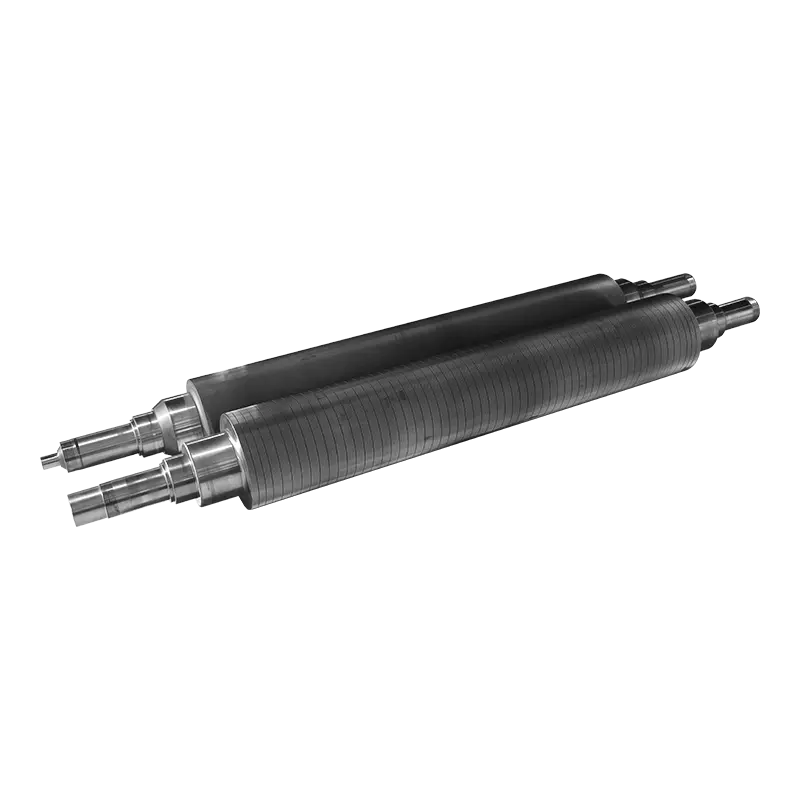

The primary function of pressure rolls is to apply a uniform amount of pressure to the material moving through the machine. This pressure is essential for processes such as smoothing, compressing, or shaping the material. In a pressure roll factory, the design and construction of the rolls are optimized to ensure they perform efficiently in these processes. These rolls are typically made from durable materials such as steel, rubber, or polyurethane, which allow them to withstand high levels of pressure without compromising their functionality.

In the pressure roll factory, the manufacturing process involves several steps to ensure that each roll is constructed to meet the desired specifications. First, raw materials are carefully selected based on the type of pressure roll required. Steel pressure rolls, for example, need to be forged and treated to achieve the right level of hardness, while rubber rolls may undergo a vulcanization process to enhance their durability. Once the materials are prepared, the rolls are machined to the precise dimensions needed for their respective applications.

One of the key advantages of working with a pressure roll factory is the ability to customize rolls for specific requirements. Not all applications require the same type of pressure roll, and a factory that specializes in pressure rolls can design and manufacture rolls to meet the specific needs of a particular production line. Whether it's adjusting the size, material, or texture of the roll surface, a pressure roll factory has the expertise to create the ideal product for the job.

In addition to custom designs, a pressure roll factory also focuses on the durability and longevity of the rolls. High-quality pressure rolls are essential for maintaining consistent production speeds and minimizing downtime caused by roll wear or failure. A well-constructed pressure roll can operate for extended periods, even under heavy loads, which helps reduce maintenance costs and improve the overall efficiency of the machinery.

Another important consideration when working with a pressure roll factory is the level of precision in the manufacturing process. Even slight variations in the roll's dimensions can affect the quality of the final product. For example, a roll that is too smooth or too rough can result in inconsistent pressure, leading to defects in the processed material. A reputable pressure roll factory ensures that every roll is made to exacting standards, using advanced measuring and testing equipment to verify the roll's performance before it is shipped out.

In addition to producing pressure rolls for industrial machines, a pressure roll factory may also offer repair and maintenance services. Over time, pressure rolls can wear out or become damaged due to constant use, and repairing or replacing them can be costly. By working with a factory that offers repair services, businesses can extend the lifespan of their rolls and avoid the need for frequent replacements.

A pressure roll factory plays a vital role in the manufacturing and maintenance of pressure rolls that are essential for many industrial processes. Through customized designs, durable materials, and precise manufacturing techniques, these factories provide high-quality rolls that improve the efficiency and performance of machinery. Whether for new production lines or maintenance needs, a pressure roll factory offers a valuable service to industries requiring consistent and reliable pressure rolls.